In the introduction, you can start by emphasizing the importance of choosing the right thickness of 6WL stainless steel sheets for a successful project. Mention that the thickness plays a crucial role in determining the performance, durability, and cost-effectiveness of the final outcome.

Understanding Thickness Measurements

Explain that stainless steel sheet thickness is measured using two common methods: gauge and millimeters (mm). In the U.S., stainless steel sheets are often measured in gauge, while in most other countries, they are measured in millimeters.

Provide a conversion chart between gauge and millimeters for clarity and convenience.

Factors to Consider When Choosing Thickness

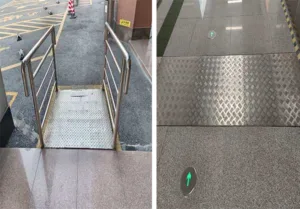

Load-Bearing Capacity

- Explain that thicker 6WL stainless steel sheets have a higher load-bearing capacity. For heavy-duty applications or projects with significant weight loads, it’s essential to choose thicker sheets to prevent deformation or structural failures.

- Provide weight and load capacity tables for different thicknesses to help readers make informed decisions.

Durability and Strength

– Describe how thicker sheets offer greater durability and strength, making them suitable for applications that require resistance to impacts or prolonged usage.

– Advise readers to consider the potential wear and tear the stainless steel sheets might experience in their specific projects and select an appropriate thickness accordingly.

Environmental Conditions

– Explain how the project’s environment, such as exposure to harsh weather conditions, chemicals, or corrosive substances, can impact the longevity of the stainless steel sheets.

– Suggest using thicker sheets for projects in harsh environments to ensure extended service life and resistance to corrosion.

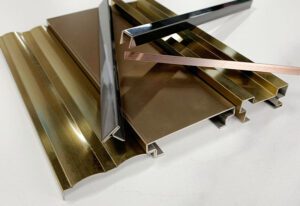

Common Thickness Options and Applications

Thin Sheets (e.g., 0.5mm – 1.0mm)

- Discuss the applications where thin 6WL stainless steel sheets are suitable, such as decorative purposes, lightweight structures, or projects with minimal load requirements.

- Provide examples of projects where thin sheets have been used effectively and share insights on their advantages in these scenarios.

Medium Thickness (e.g., 0.3mm – 2.0mm)

- Explain the versatility of medium-thickness sheets and their common use in various industries, including architecture, interior design, and automotive applications.

- Highlight that medium-thickness sheets strike a good balance between load-bearing capacity and cost-effectiveness, making them a popular choice for many projects.

Thick Sheets (e.g., 3.0mm and above)

- Highlight the applications that demand thicker 6WL stainless steel sheets, such as heavy machinery, industrial equipment, or projects that require exceptional strength and durability.

- Advise readers to opt for thicker sheets in projects that involve high-stress conditions or where safety and longevity are paramount.

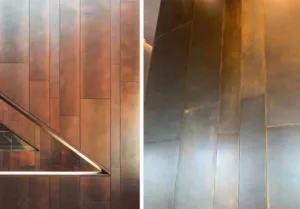

The Visual Appeal of 6WL Textures and Their Application in Decorative Projects

- The texture of 6WL Stainless Steel Decorative Plate is unique and beautiful, which can add a modern and stylish touch to the project.

- Applicable to various decoration projects, such as interior decoration, building facade, sculpture art, etc., bringing a different visual experience to the project.

The beauty of texture: exploring the unique texture of 6WL stainless steel decorative panels

A. Describe the texture characteristics and surface treatment methods of 6WL stainless steel decorative panels

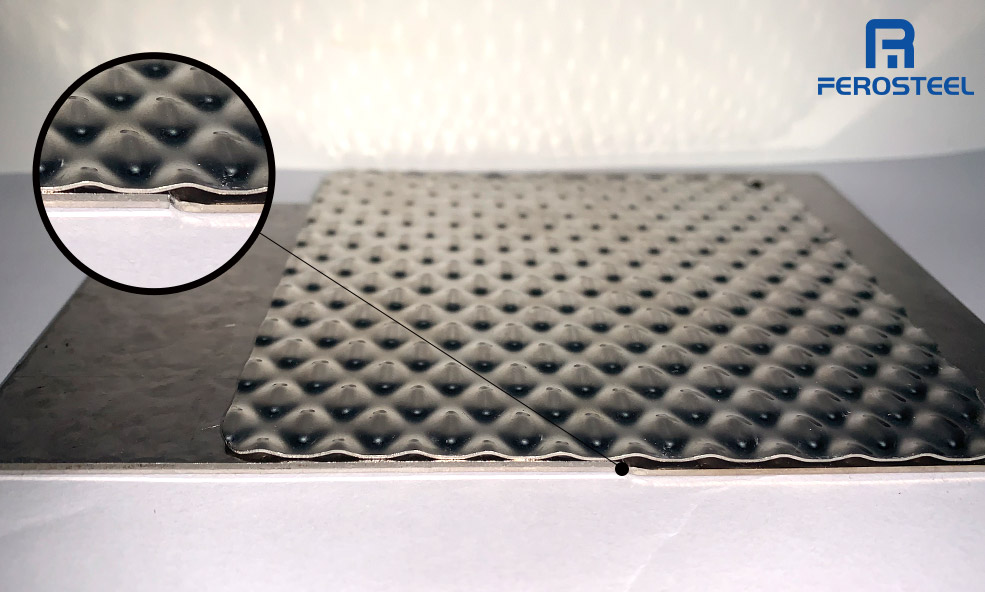

- The 6WL texture is characterized by a hexagonal grid arrangement, each grid has a certain depth and height, forming a clear sense of bumps.

- The surface treatment method can be brushed, laser or acid-etched to make the texture more prominent and enhance the visual effect.

B. Show the visual effect of 6WL texture under different lighting conditions - Under different angles and light, the texture of the 6WL stainless steel decorative panel will produce rich light and shadow changes, presenting a unique visual effect.

6wl stainless steel sheets FAQs

How can I maintain the appearance of 6WL stainless steel sheets?

Maintaining the appearance of 6WL stainless steel sheets is straightforward. You can use a soft cleaning cloth or sponge dipped in a mild detergent to wipe the surface and then rinse with water and dry it. Avoid using cleaners containing ammonia, chlorine, or acidic components as they may damage the stainless steel surface. Regular cleaning and maintenance will help preserve the beauty and durability of the decorative panels.

What are the available thickness options for 6WL stainless steel sheet?

6WL stainless steel sheets are typically available in thicknesses ranging from 0.5mm to 3.0mm. Different thicknesses are suitable for different project requirements. Thinner decorative sheets are suitable for light-load indoor decorations, while thicker sheets are ideal for building facades, heavy-duty applications, and projects with specific structural demands.

How is the texture of 6WL stainless steel sheets created?

The texture of 6WL stainless steel sheets is achieved through advanced processing techniques. It is typically created using embossing or laser technology to form a hexagonal grid pattern on the surface of the stainless steel sheet, resulting in distinct concave and convex impressions and creating the unique 6WL texture.