Mirror stainless steel sheets are widely used in architectural decoration, home design, and electronic product casings due to their high gloss and excellent corrosion resistance. Not only are they visually appealing, but they also significantly enhance the durability of the products they are used in. This article provides a detailed breakdown of the mirror stainless steel sheet processing, key techniques involved, and its wide-ranging applications.

1. Overview of Mirror Stainless Steel Sheets

Mirror stainless steel sheets refer to stainless steel materials that have undergone polishing to achieve a mirror-like finish. The surface is smooth and reflective, providing a high degree of brightness. Common materials include 304 and 316 stainless steel, known for their excellent corrosion resistance, mechanical properties, and weldability, making them popular choices in the market.

2. Main Types of Mirror Stainless Steel

Mirror stainless steel sheets can be categorized based on surface smoothness, reflectivity, and polishing techniques:

- 8K Mirror Stainless Steel: Used in high-end architectural settings, with a reflective effect close to that of a mirror.

- 6K Mirror Stainless Steel: Slightly less glossy than 8K but still offers a good reflective quality.

- 10K Mirror Stainless Steel: Offers extremely fine polishing, mainly used in luxury showcases and high-end furniture.

3. Preparation for Mirror Stainless Steel Processing

Before processing mirror stainless steel sheets, the base material must be of high quality. The surface should be free from visible scratches, dents, or impurities, as these imperfections will affect the polishing outcome. Additionally, preliminary grinding and cleaning are required to ensure a smooth polishing process.

4. Processing Steps of Mirror Stainless Steel Sheets

The processing of mirror stainless steel sheets typically involves several steps, each requiring specialized equipment and techniques to achieve a high gloss finish.

4.1 Initial Grinding

The purpose of initial grinding is to remove rough spots on the stainless steel surface, making it relatively smooth. Coarse abrasives (such as 120-grit or 240-grit belts) are used for mechanical grinding. This step helps eliminate surface oxidation, burrs, or weld marks, laying the foundation for finer polishing.

4.2 Intermediate Grinding and Polishing

After the initial grinding, intermediate grinding is done using medium-grit abrasives (such as 400-grit belts) to smooth the surface further. Pre-polishing follows, where finer abrasives (such as 600-grit or 800-grit wheels) are used to enhance the surface’s smoothness.

4.3 Fine Polishing (8K or 10K Finish)

In the fine polishing stage, ultra-fine abrasives (such as 2000-grit or higher) are applied multiple times to achieve a highly glossy, mirror-like surface. This stage is referred to as 8K or 10K polishing, depending on the final level of surface gloss required. Polishing compounds are often used to improve efficiency and minimize scratches during this process.

4.4 Surface Cleaning

Once polishing is complete, residues such as polishing compounds, oils, and small particles are left on the surface. These must be thoroughly cleaned with specialized cleaning agents to ensure a pure mirror finish.

5. Surface Treatment Techniques for Mirror Stainless Steel

In addition to polishing, mirror stainless steel sheets often undergo extra surface treatments to improve durability and aesthetics:

- Electroplating: Adds a protective layer to enhance corrosion resistance and can give the stainless steel different colors, such as gold or rose gold.

- Titanium Coating: Titanium treatment improves the hardness and wear resistance of the surface, while also allowing for a variety of color finishes.

- Anti-Fingerprint Coating: To prevent smudges from fingerprints, an anti-fingerprint coating can be applied, ensuring the mirror-like finish remains pristine over time.

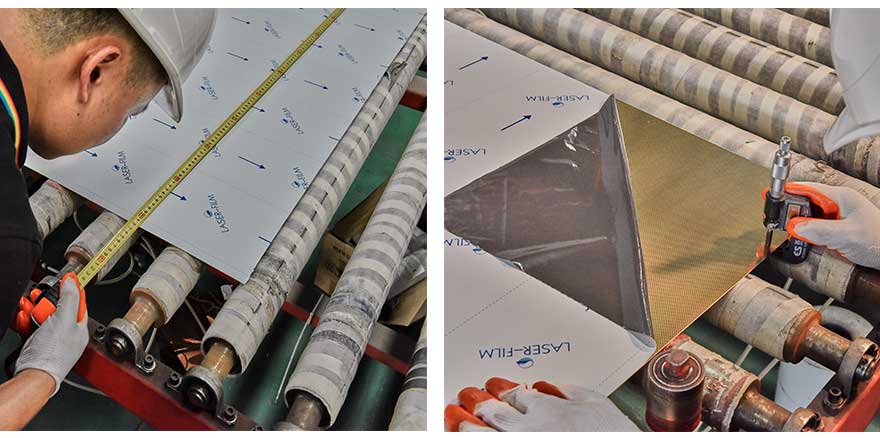

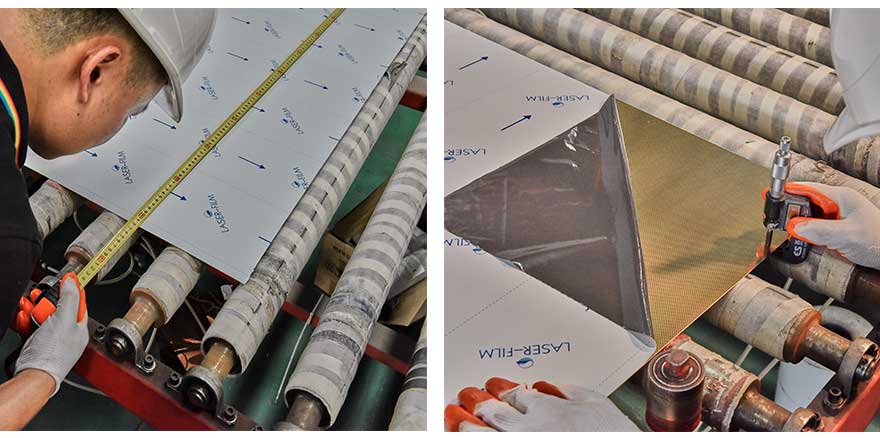

6. Quality Control for Mirror Stainless Steel

Quality control is critical throughout the processing of mirror stainless steel sheets. Factors such as the uniformity of polishing, the degree of surface scratching, and the purity of reflected light all contribute to the final product quality. Rigorous quality checks are typically performed, including gloss measurements, flatness checks, and corrosion resistance tests, to meet customer requirements.

7. Applications of Mirror Stainless Steel Sheets

Due to their high gloss and excellent physical properties, mirror stainless steel is widely used in various fields:

- Architectural Decoration: Used in curtain walls, elevator panels, ceilings, and decorative columns, mirror stainless steel enhances modern architecture’s sophistication and luxury.

- Home and Kitchen Products: Found in stainless steel cabinets, refrigerator panels, and kitchen utensils, mirror stainless steel is not only aesthetically pleasing but also easy to clean.

- Electronic Devices: Many high-end electronic products, such as smartphones and laptops, use mirror stainless steel for their casings to improve the overall look and feel.

- Artwork and Display Cabinets: In high-end jewelry display cabinets and art exhibitions, mirror stainless steel reflects the surrounding environment, further highlighting the unique features of the exhibited items.

8. Key Considerations in Mirror Stainless Steel Processing

Several important details must be considered during the processing of mirror stainless steel:

- Preventing Scratches: Since the surface is extremely smooth, any scratches will be highly visible. During processing and transport, protective films should be applied to prevent contact with hard objects.

- Environmental Conditions: The cleanliness of the polishing environment significantly affects the final mirror effect. The polishing workshop must be free of dust and oil to avoid contaminants adhering to the sheet surface.

- Uniform Polishing: To achieve a uniform mirror finish across the entire surface, consistent pressure must be applied during polishing to avoid uneven areas.

9. Frequently Asked Questions

1. What is 8K polishing for stainless steel?

8K polishing refers to a surface treatment where stainless steel is polished to a mirror-like gloss, capable of clearly reflecting objects.

2. Is mirror stainless steel prone to scratches?

Due to its smooth surface, mirror stainless steel is more prone to visible scratches than other types. Extra care should be taken during use to avoid contact with sharp objects.

3. Is mirror stainless steel suitable for outdoor use?

Mirror stainless steel can be used outdoors, but it is recommended to use 304 or 316 stainless steel, as they have better corrosion resistance to withstand harsh outdoor conditions.

4. How do I clean mirror stainless steel?

Use specialized stainless steel cleaners or a mild solution of water and neutral detergent. Wipe with a soft cloth and dry afterward for a streak-free shine.

5. Does mirror polishing affect the performance of stainless steel?

Polishing only alters the surface appearance and does not significantly affect the mechanical or corrosion-resistant properties of the stainless steel.

6. What are the common thicknesses of mirror stainless steel sheets?

Typical thicknesses for mirror stainless steel sheets range from 0.5mm to 3mm, with the specific choice depending on the application.

10. Conclusion

Mirror stainless steel sheets, with their unique gloss and excellent properties, have become indispensable in modern industry, architecture, and design. Whether in high-end architectural decoration or household products, the future of mirror stainless steel applications is bright. Through precise processing techniques and strict quality control, the surface smoothness of mirror stainless steel sheets can meet the highest demands, making them a standout feature in any design.