In interior design, the materials you choose often determine the overall atmosphere of a space. As modern design trends evolve, more innovative materials are introduced, and water ripple stainless steel sheets are undoubtedly one of the most captivating options. These sheets not only stand out for their visual impact but also for their durability, versatility, and environmental benefits. Whether in high-end commercial spaces or residential interiors, water ripple stainless steel sheets can inject life and a modern touch into any design, making them a preferred choice for both designers and homeowners.

What Are Water Ripple Stainless Steel Sheets?

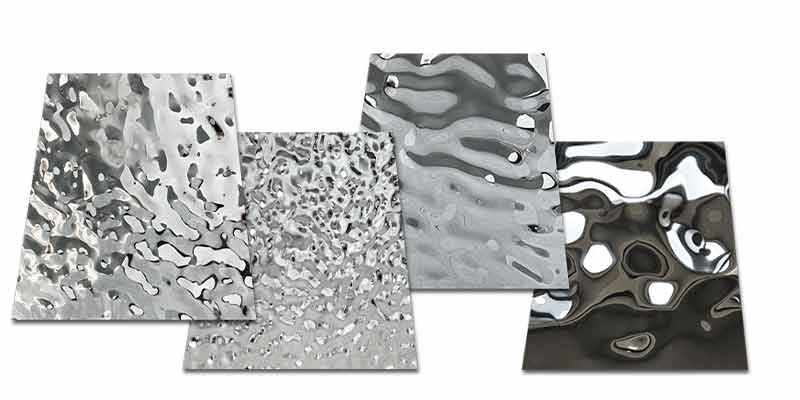

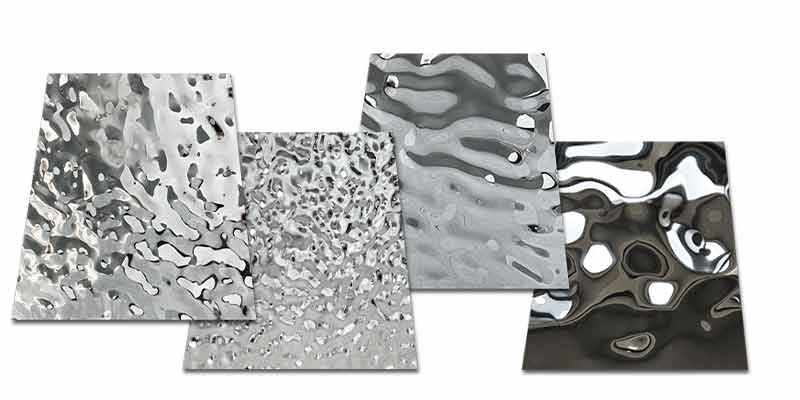

Water ripple stainless steel sheets are characterized by unique surface patterns that resemble the gentle ripples of water. Their wave-like texture creates depth and movement, which changes with the angle of light. This effect not only provides a striking visual impact but also interacts with different lighting sources, offering a dynamic and sophisticated appearance.

Typically made from high-quality stainless steel, these sheets are processed using advanced techniques such as PVD (Physical Vapor Deposition), mirror finishing, and brushing, enhancing their strength and visual appeal. This processing also improves their resistance to corrosion and oxidation, ensuring that their aesthetic and durability remain intact over time.

Benefits of Water Ripple Stainless Steel Sheets

1. Unique Visual Appeal

The most distinctive feature of water ripple stainless steel sheets is their surface pattern. The undulating waves create irregular light reflections that add depth and dimension to any space. Depending on the light angle, the ripple effect shifts, providing a dynamic and ever-changing visual experience. Whether used for feature walls, ceilings, or decorative panels, water ripple stainless steel sheets can elevate the aesthetic of any space with their luxurious and modern appeal.

2. Durability and Strength

Stainless steel is known for its exceptional strength and durability. Water ripple stainless steel sheets are no exception. They are highly resistant to corrosion, oxidation, and scratching, making them perfect for high-traffic areas or spaces exposed to moisture, such as shopping malls, hotels, or elevators. Additionally, stainless steel’s resilience means that these sheets will maintain their appearance over time, minimizing maintenance requirements.

3. Reflective Properties

The wave-like surface structure of water ripple stainless steel sheets creates fascinating lighting effects. As light interacts with the surface, it produces various reflections, adding depth and dimension to the space. Whether used on ceilings or walls, this ripple design can transform a room, especially when illuminated, by providing a shimmering and dynamic visual effect.

4. Sustainability

Stainless steel is an eco-friendly material due to its recyclability. Water ripple stainless steel sheets have a long lifespan, meaning they require less frequent replacement, which reduces waste. Additionally, the recyclability of stainless steel means that these materials can be reused during renovations or construction projects, minimizing environmental impact.

Applications of Water Ripple Stainless Steel Sheets

The versatility of water ripple stainless steel sheets allows them to be used in various design contexts, from commercial spaces to residential homes. Here are some common applications:

1. Background Walls in Commercial Spaces

Water ripple stainless steel sheets are frequently used as feature walls in high-end commercial environments. The unique ripple effect creates a striking visual focal point, enhancing the modern and luxurious feel of spaces. Whether in shopping malls, hotel lobbies, or restaurants, water ripple sheets for background walls add texture, depth, and a dynamic aesthetic to the space.

2. Ceiling Designs

In both residential and commercial interiors, water ripple stainless steel sheets are widely used for ceiling treatments. Not only do they break the monotony of flat ceilings, but the wave patterns interact with the light to create mesmerizing effects. In large spaces such as lobbies, conference rooms, or restaurants, water ripple ceilings can enhance the ambiance and give the room a luxurious and sophisticated feel.

3. Elevator Interiors

Water ripple stainless steel sheets are popular in elevator interiors, particularly in high-end office buildings, hotels, and luxury residences. The reflective nature of the material makes elevators appear brighter and more spacious. Additionally, the durability of the sheets ensures that the interior retains its visual appeal over time, minimizing the need for frequent maintenance or replacement.

4. Partitions in Hotels or Restaurants

Water ripple stainless steel sheets are commonly used for space partitions in restaurants and hotels. The wave pattern not only provides a functional partitioning solution but also serves as a decorative element. These partitions help divide spaces effectively without making the room feel cramped or segmented, particularly in open-plan layouts.

5. Decorative Panels in Kitchens and Bathrooms

Water ripple stainless steel sheets are ideal for use in kitchens and bathrooms due to their water-resistant and easy-to-maintain properties. Used for backsplashes, feature walls, or kitchen islands, they provide durable surfaces while enhancing the aesthetic of the space. The reflective surface of the sheets interacts with water and light to create a dynamic and vibrant feel.

6. Furniture Design

Water ripple stainless steel sheets are also widely used in custom furniture design. Whether as countertops, dining tables, or cabinetry, the ripple effect adds modern and artistic appeal to furniture pieces. Their durability ensures they perform well in high-use areas, making them both functional and stylish.

7. Decorative Screens or Partition Strips

Water ripple stainless steel sheets are frequently used to create decorative screens or partition strips in interior spaces. These screens divide spaces while enhancing the overall aesthetic. Whether in offices, homes, or commercial settings, water ripple designs bring elegance and movement to the space, making it feel more dynamic.

8. Facade Decoration in Luxury Hotels

In luxury hotels, water ripple stainless steel sheets are used to create stunning facades. The reflective properties of the material interact with the surrounding environment and light, enhancing the building’s visual appeal. At night, the illuminated water ripple surface creates a mesmerizing effect, drawing attention to the architectural beauty of the structure.

Frequently Asked Questions (FAQ)

1. How durable are water ripple stainless steel sheets?

Water ripple stainless steel sheets are highly durable, offering excellent resistance to corrosion, oxidation, and scratching. They are ideal for high-traffic and humid environments, making them perfect for commercial spaces, kitchens, and bathrooms.

2. Can the color and depth of the ripple be customized?

Yes, water ripple stainless steel sheets can be customized according to your needs. You can choose from different ripple depths, colors, and surface finishes (such as PVD coating, mirror finish, etc.) to match your design requirements.

3. Where are water ripple stainless steel sheets best used?

Water ripple stainless steel sheets are widely used in commercial spaces (such as malls, hotels, and restaurants), residential areas (such as living rooms, kitchens, and bathrooms), and custom furniture applications. Their unique visual appeal and durability make them ideal for a variety of settings.

Solutions

1. How to address maintenance challenges with water ripple stainless steel sheets?

Although water ripple stainless steel sheets are highly resistant to dirt and stains, regular cleaning is important to maintain their longevity. Use a soft cloth and mild cleaning solutions, and avoid using sharp objects that could scratch the surface. Additionally, regularly check seams and edges to prevent water from penetrating and causing damage over time.

2. How to solve the color variation problem in water ripple stainless steel sheets?

Color variations may arise due to differences in production batches or lighting conditions. To ensure consistency, it is recommended to source sheets from the same batch and avoid excessive exposure to direct sunlight. If uniformity in color is required, consider opting for a PVD coating to maintain a consistent appearance across all panels.

3. How to choose the right thickness for water ripple stainless steel sheets?

The thickness of water ripple stainless steel sheets depends on the intended use and environmental factors. For commercial spaces and high-end projects, thicker sheets are recommended for enhanced durability. For lighter decorative applications, thinner sheets can be used to achieve the desired aesthetic without adding excessive weight.

If you want to learn more or explore various patterns of water ripple stainless steel, visit the Color Metals Water Ripple Pattern for more options.