Introduction

A. Definition of stainless steel #4 finish

Stainless steel #4 finish refers to a specific type of surface finish characterized by a brushed appearance with a non-directional grain pattern. It is achieved by mechanically polishing the surface of stainless steel with abrasive materials, resulting in a smooth, matte finish.

B. Importance of stainless steel No.4 finish in various industries

Stainless steel No.4 finish plays a crucial role in a wide range of industries, including architecture, food processing, pharmaceuticals, automotive, and aerospace. Its aesthetic appeal, durability, and hygienic properties make it a preferred choice for numerous applications.

C. Overview of the benefits of using stainless steel No.4 finish

The benefits of stainless steel #4 finish are manifold. It offers an attractive appearance, exceptional durability, corrosion resistance, and ease of maintenance. These qualities make it suitable for both decorative and functional purposes across various industries.

Characteristics of stainless steel #4 finish

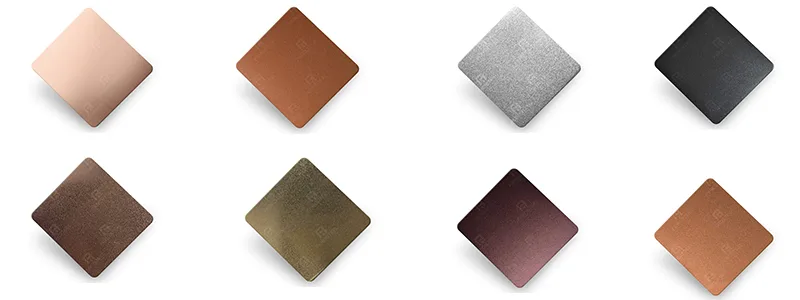

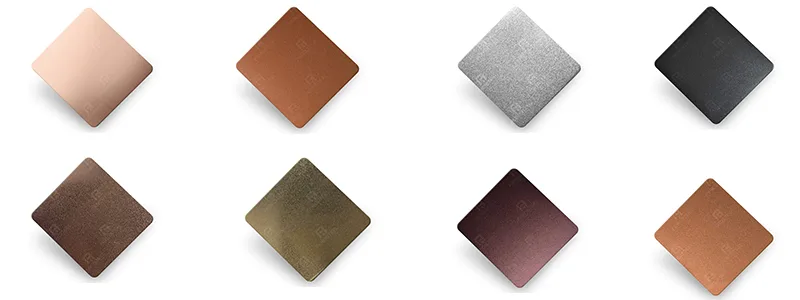

A. Texture and appearance

Stainless steel #4 finish is characterized by its brushed texture, which imparts a subtle sheen and uniform grain pattern to the surface. This distinctive aesthetic enhances the visual appeal of architectural elements, machinery, and consumer products.

B. Durability and corrosion resistance

One of the key characteristics of stainless steel No.4 finish is its exceptional durability and resistance to corrosion. This makes it ideal for applications where exposure to moisture, chemicals, or harsh environments is common, ensuring long-term performance and reliability.

C. Maintenance and cleaning requirements

Maintaining stainless steel #4 finish is relatively simple. Regular cleaning with mild soap and water is usually sufficient to remove dirt, fingerprints, and other surface contaminants. Avoiding abrasive cleaners and harsh chemicals helps preserve the finish and extend its lifespan.

Applications of stainless steel #4 finish

A. Architectural and design uses

Stainless steel #4 finish is widely used in architectural and interior design for its modern aesthetic and versatility. It is often seen in building facades, handrails, elevator doors, countertops, and decorative panels, adding a touch of sophistication to any space.

B. Food processing and pharmaceutical industries

In the food processing and pharmaceutical industries, cleanliness and hygiene are paramount. Stainless steel #4 finish meets these requirements with its smooth, non-porous surface that resists bacterial growth and is easy to sanitize, making it ideal for equipment, fixtures, and surfaces in these sectors.

C. Automotive and aerospace applications

In automotive and aerospace applications, stainless steel #4 finish is valued for its combination of strength, durability, and aesthetic appeal. It is used in vehicle trim, exhaust systems, interior components, and aircraft interiors, where performance and aesthetics are equally important.

Advantages of using stainless steel #4 finish

A. Aesthetics and visual appeal

Stainless steel #4 finish enhances the aesthetics of any product or structure, providing a sleek, contemporary appearance that complements modern design themes.

B. Longevity and low maintenance

With its durable construction and corrosion-resistant properties, stainless steel No.4 finish offers long-term performance and requires minimal maintenance, reducing lifecycle costs and ensuring lasting value.

C. Hygienic properties and ease of cleaning

The smooth, non-porous surface of stainless steel #4 finish makes it easy to clean and sanitize, making it an ideal choice for applications where hygiene is critical, such as food processing facilities, hospitals, and laboratories.

How to achieve and maintain stainless steel #4 finish

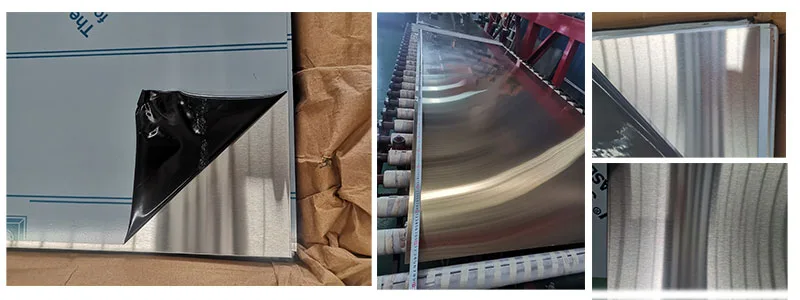

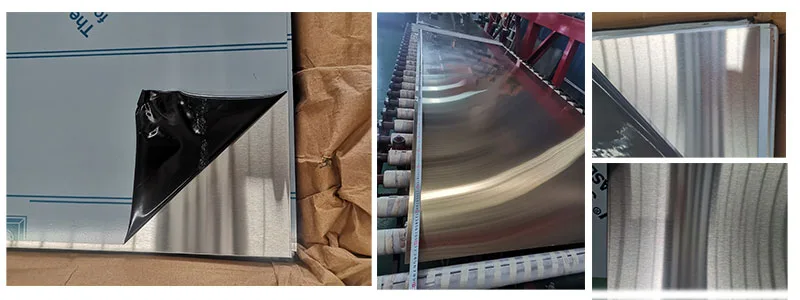

A. Fabrication and finishing processes

Stainless steel #4 finish is achieved through mechanical polishing and brushing techniques, which produce a consistent, uniform grain pattern across the surface. Careful attention to detail during fabrication ensures optimal results.

B. Cleaning and maintenance tips

To maintain the appearance and performance of stainless steel No.4 finish, regular cleaning with mild soap and water is recommended. Avoid abrasive cleaners and harsh chemicals, as these can damage the finish and compromise its integrity.

C. Common mistakes to avoid when working with stainless steel #4 finish

Common mistakes when working with stainless steel #4 finish include using abra sive materials or harsh chemicals for cleaning, neglecting routine maintenance, and improper handling during fabrication and installation. Avoiding these pitfalls helps preserve the finish and prolong its lifespan.

Conclusion

In conclusion, stainless steel No.4 finish offers a winning combination of aesthetics, durability, and functionality, making it an indispensable material in various industries. As technology advances and design trends evolve, we can expect to see continued innovation and expansion in the use of stainless steel #4 finish, further solidifying its position as a versatile and indispensable material for modern