The artistry of design meets the resilience of stainless steel in the exquisite technique known as Bead Blasted Finish on Stainless Steel. This method, a testament to the fusion of aesthetics and durability, has become a transformative force in the world of architectural embellishment and design refinement.

Elevating stainless steel beyond its utilitarian origins, Bead Blasted Finish on Stainless Steel imparts a subtle yet distinctive texture, creating a canvas of sophistication and modernity. In this exploration, we delve into the nuanced realm of Bead Blasted Finish on Stainless Steel, unraveling its craftsmanship, unraveling its diverse applications, and unveiling its impact on the intersection of style and functionality.

Characteristics of Bead Blasted Finish on Stainless Steel

Sandblasted trim has several significant features that make it a popular choice for stainless steel.

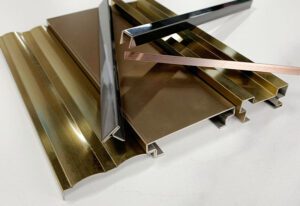

Versatility: Sandblasting can be applied to a variety of metals, including stainless steel, titanium, aluminum, copper, and brass. This versatility offers creative design possibilities for a variety of industries and applications.

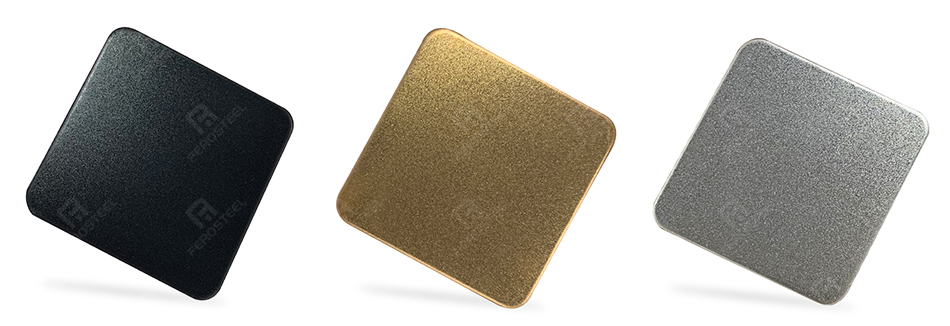

Aesthetic: Bead Blasted Finish on Stainless Steel to create a beautiful silvery-white finish that resembles the look of jewelry. It adds a touch of sophistication and elegance to architectural elements, handrails, sculptures, and other stainless steel products.

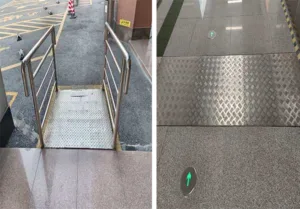

Durability: Bead Blasted Finish on Stainless Steel is highly resistant to scratches, abrasion, and abrasion. This makes them ideal for high-flow areas, such as elevators, columns, and cladding, where surfaces can be subject to frequent contact and potential damage.

Paint Adhesion: The textured surface formed by sandblasting improves the adhesion of the paint coating, making it easier to apply and ensuring a long-lasting finish. This makes Bead Blasted Finish on Stainless Steel an excellent choice for products that require painting or powder coating.

Application of Bead Blasted Finish on Stainless Steel

Stainless steel sandblasting is widely used in various industries.

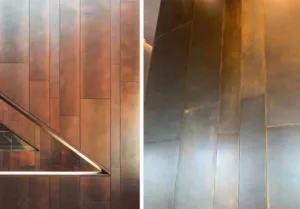

Architectural Design: Sandblasted stainless steel is commonly used in indoor and outdoor construction projects. It adds a modern and sophisticated touch to building facades, wall panels, ceilings, and decorative elements such as mashrabiyas.

Handrails and railings: Sandblasting enhances the appearance of handrails, giving them a soft and elegant appearance. It is especially suitable for handrails in public places where durability and aesthetics are equally important.

Elevator interiors: Sandblasted stainless steel is a great choice for elevator interiors because it provides a visually consistent and durable finish. Its non-reflective surface reduces glare and fingerprints, maintaining a clean, stylish appearance.

Cladding and exterior walls: The stainless steel cladding is sandblasted to provide both protection and aesthetics. The sandstone-like texture enhances the visual appeal of the structure and provides long-lasting corrosion resistance, ensuring a service life of more than 15 years.

Sculptures and Art Installations: Sandblasted stainless steel has become a popular choice for creating sculptures and art installations due to its unique texture and durability. It allows artists to express their creativity while ensuring long-term preservation.

The advantages of sandblasted stainless steel

Compared with other surface treatments, stainless steel sandblasting has several advantages:

Rich color options: Sandblasted stainless steel can be customized in a variety of colors, giving designers and architects the freedom to create visually striking unique designs. Colors can be applied through techniques such as physical vapor deposition (PVD), offering a variety of options such as burgundy, bronze, graphite, and more.

Long service life: The stainless steel surface naturally forms a protective passivation film, which has excellent corrosion resistance. Although sandblasting may weaken this natural film, manufacturers can apply additional passivation films to improve the longevity and corrosion resistance of the surface finish.

Multiple treatment types: Sandblasting can be performed using different methods, including automatic (wheeled) sandblasting, air blasting, and water blasting. Each method offers unique advantages and allows for precise control of the texture and finish of stainless steel.

Easy to maintain: The Bead Blasted Finish on Stainless Steel is easy to clean and maintain. Dust, dirt and fingerprints can be easily wiped off with a microfiber cloth or a mild soap solution. Specialized cleaning products, such as Wright’s Copper Cream or Flitz Brass & Copper Tarnish Remover, can be used on specific metals such as copper.

How to achieve a sandblasted finish

In order to achieve high-quality sandblasting on stainless steel, the following factors need to be considered:

Surface treatment: Before sandblasting, the stainless steel surface must be properly treated. This includes removing any dirt, grease or contaminants to ensure optimum adhesion and surface quality.

Selection of sandblasting media: The choice of sandblasting media (e.g. glass beads, zirconia, or alumina) depends on the desired texture and finish. Different media can result in different degrees of roughness and surface appearance.

Equipment and technology: Sandblasting is a delicate process that requires precise control of parameters such as media type, injection volume, distance, and pressure. Skilled operators with experience in sandblasting techniques can achieve consistent and repeatable results.

Protective measures: During sandblasting, it is important to take appropriate safety measures to protect the environment and operators. This includes the use of closed sandblasting cabinets or appropriate ventilation systems to control dust and abrasive particles.