In contemporary architecture and interior design, brushed metal surface treatments and brushed stainless steel sheets are increasingly becoming favored choices. They not only enhance the visual appeal of products and spaces but also offer exceptional durability and ease of maintenance. This article delves into the fundamental concepts, advantages, and diverse applications of brushed metal surface treatments, particularly focusing on brushed stainless steel sheets.

Fundamental Concepts of Brushed Metal Surface Treatment

Brushed metal surface treatment involves creating fine textured patterns on metal surfaces using mechanical means. These patterns can range from linear to circular or even intersecting designs, each imparting a unique aesthetic and tactile quality to the metal. Commonly used metals for brushing include stainless steel, aluminum, and brass, each chosen for its suitability in different design applications across architecture, furniture manufacturing, and industrial settings.

Advantages of Brushed Metal Surface Treatment

- Aesthetic Appeal and Modern Sensibility: Brushed metal finishes impart a sophisticated and modern appearance to products and spaces, aligning perfectly with contemporary design aesthetics. Whether used in interior design or as architectural elements, the brushed texture elevates the overall look and feel, adding a touch of elegance and high-end appeal.

- Durability: The brushing process enhances the surface durability of metals, making them more resistant to wear and corrosion. This durability significantly extends the lifespan of products, reducing long-term maintenance costs and efforts.

- Ease of Maintenance: Brushed surfaces are inherently resistant to fingerprints and smudges, making them easier to clean and maintain compared to glossy or polished finishes. Routine cleaning requires only mild cleansers and soft cloths to keep the surfaces looking pristine.

Characteristics of Brushed Stainless Steel Sheets

Brushed stainless steel sheets are particularly valued for their strength, corrosion resistance, and aesthetic versatility:

- Material Characteristics: Typically made from high-grade stainless steel such as 304 or 316, these sheets offer excellent corrosion resistance and mechanical strength, suitable for a wide range of indoor and outdoor applications.

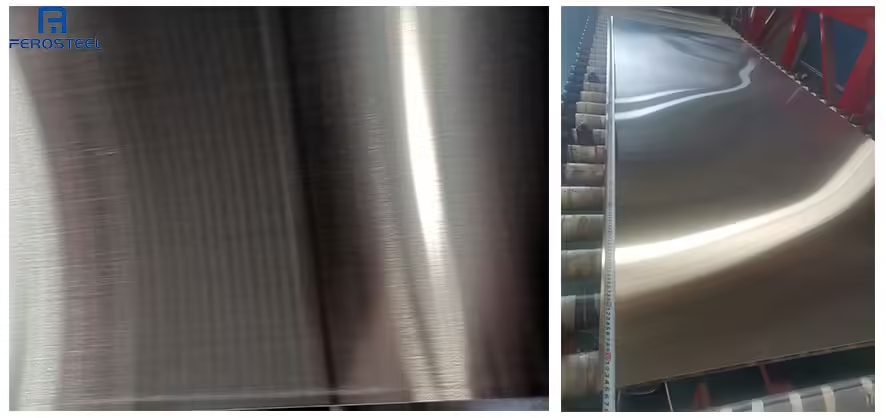

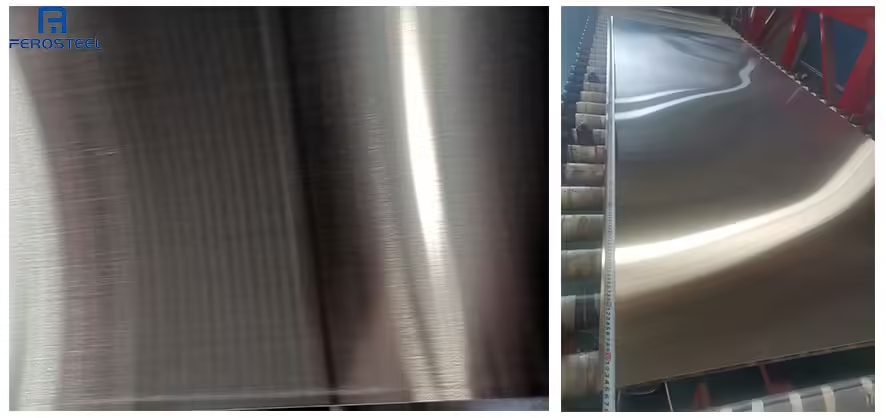

- Surface Finish Options: After brushing, stainless steel sheets exhibit a distinctive texture and sheen. Different brushing techniques—straight line, circular, or cross-hatch patterns—provide designers with flexibility to achieve various visual effects, catering to diverse design styles and preferences.

Production and Processing of Brushed Stainless Steel Sheets

Producing high-quality brushed stainless steel sheets involves advanced manufacturing techniques and meticulous processing:

- Production Process: From material selection to the final finishing stages, the production of brushed stainless steel sheets involves multiple steps such as brushing, polishing, and cleaning. Advanced equipment and skilled craftsmanship ensure consistency and superior quality in the finished products.

- Processing Techniques: Achieving uniform and high-quality brushed effects requires precise control and expertise to avoid surface damage and ensure consistency throughout the processing stages.

Applications of Brushed Stainless Steel Sheets

Brushed stainless steel sheets find wide-ranging applications across various industries and sectors:

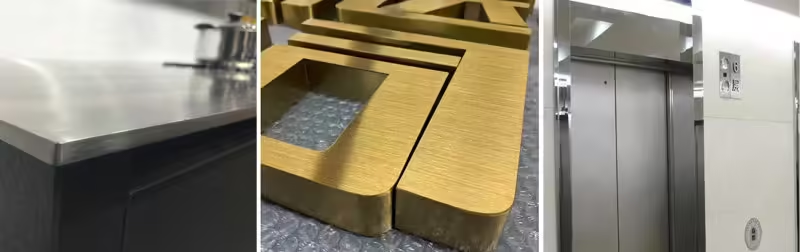

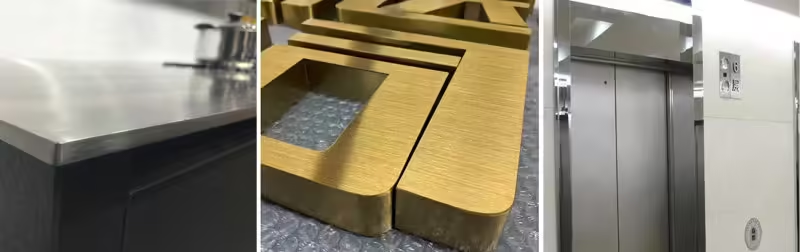

- Architecture and Decoration: Used in modern architectural facades, interior decoration, lobby areas, and elevator interiors, brushed stainless steel sheets enhance the visual appeal and upscale ambiance of buildings.

- Home and Furniture: In home decor and furniture manufacturing, these sheets are employed in kitchen appliances, cabinet doors, tabletops, and other furnishings, imparting a contemporary and sophisticated look while ensuring durability and practicality.

- Industrial and Commercial Uses: They are integral in manufacturing industrial equipment, commercial kitchen appliances, and automotive components due to their corrosion resistance and easy-clean properties.

- Other Industries: Applications extend to medical devices, electronics, and consumer goods where hygiene, durability, and aesthetic appeal are paramount.

Product Specifications

- Material: Typically 304 or 316 grade stainless steel for superior corrosion resistance and mechanical strength.

- Thickness: Ranges commonly from 0.5mm to 3.0mm, tailored to specific application requirements.

- Dimensions: Standard sizes include 1000mm x 2000mm, 1219mm x 2438mm, with options for customization to suit unique project needs.

- Surface Treatment: Offered in various brushed finishes to accommodate different design aesthetics and functional demands.

- Corrosion Resistance: Exhibits excellent resistance to corrosion, suitable for high-humidity and corrosive environments.

- Application Environments: Suitable for indoor and outdoor architectural decoration, home furnishings, industrial equipment, medical devices, electronics, and more.

Maintenance and Care

To maintain the pristine appearance and functionality of brushed stainless steel sheets:

- Regular Cleaning: Use mild cleaning agents and non-abrasive cloths to remove dirt and maintain the surface’s luster.

- Preventive Maintenance: Protect against scratches and damage by using protective films. Regular inspections and timely repairs prevent minor damages from escalating.

Conclusion

In conclusion, brushed metal surface treatments and brushed stainless steel sheets offer a compelling blend of aesthetic appeal, durability, and ease of maintenance, making them indispensable choices in modern architecture and design. With their versatility and practical benefits demonstrated across various applications, these materials continue to define contemporary aesthetics and functional excellence in diverse industries.