Table of Contents

- Introduction

- What is stainless steel?

- Overview of stainless steel sheets prices

- What factors affect the price of stainless steel plates?

- Introduction to 316 stainless steel

- 304 Stainless Steel Introduction

- 316 vs. 304 Stainless Steel Sheets

- Corrosion resistance comparison

- Application of 316 stainless steel sheets

- Application of 304 stainless steel sheets

- How to choose 316 vs. 304 stainless steel

- Common questions about stainless steel plate prices

Introduction

Stainless steel is widely used in various industries such as construction and food production due to its strength, versatility and corrosion resistance. However, not all stainless steel sheets are the same, and the price of stainless steel plates varies greatly depending on their specific materials and applications.

We will discuss the two most commonly used stainless steel grades: 304 stainless steel and 316 stainless steel. These two materials dominate the stainless steel market, but they differ in price, composition and application scenarios.

What is stainless steel?

Stainless steel is an alloy of iron, carbon and chromium, with chromium being the key element that gives stainless steel its rust-resistant properties. The most basic stainless steel contains at least 10.5% chromium, which forms a protective layer on the surface that prevents oxidation and rust.

The addition of other elements such as nickel and molybdenum further enhances the material’s durability, especially in harsh environments. Stainless steel is divided into different grades based on its composition, with 304 and 316 being the two most commonly used for stainless steel sheets.

Overview of stainless steel sheets prices

When comparing stainless steel plate prices, it is important to note that prices vary depending on factors such as the grade, thickness, and purchase volume of the stainless steel plate. Stainless steel prices are also affected by the broader metal market, such as fluctuations in the raw material prices of nickel and chromium.

Generally speaking, 316 stainless steel plates are more expensive than 304 stainless steel plates due to their higher nickel content and the presence of molybdenum. However, the specific use scenario determines the cost-effectiveness of the two materials.

What factors affect the price of stainless steel plates?

The price of stainless steel plates is affected by a variety of factors:

- Material cost: Fluctuations in the cost of raw materials such as nickel and molybdenum can affect the price of stainless steel.

- Thickness and size: Thicker stainless steel plates are more expensive due to the greater amount of material used.

- Supply and demand: Changes in demand for stainless steel in various industries can affect its price.

- Geopolitical events: Factors such as trade policies and global supply chain disruptions can affect the global price of metals.

- Production process: The production and processing costs of stainless steel can also affect the final price.

Introduction to 316 stainless steel

316 stainless steel is known for its excellent corrosion resistance, especially in chloride-containing environments. About 2-3% of molybdenum is added to its composition, which makes 316 stainless steel more durable in harsh conditions. Therefore, 316 stainless steel is often used in industries such as marine engineering, chemical processing and medical equipment.

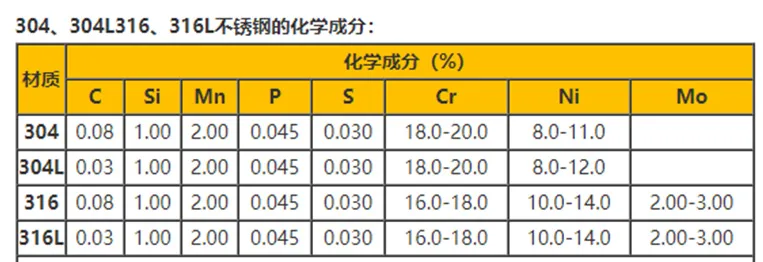

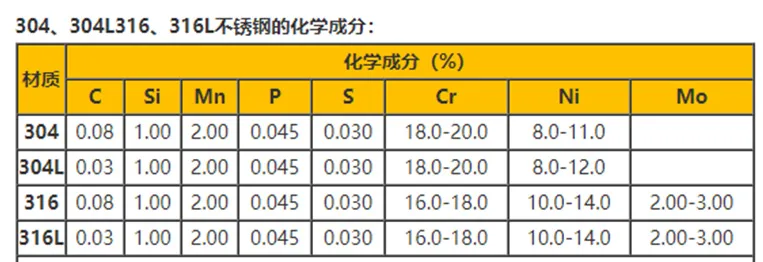

Composition of 316 stainless steel:

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

Advantages:

- Excellent corrosion resistance, especially in chloride-containing environments.

- Stronger than 304 stainless steel at high temperatures.

- Resistant to pitting and crevice corrosion in salt water environments.

304 Stainless Steel Introduction

On the other hand, 304 stainless steel is the most widely used stainless steel due to its affordability and versatility. 304 does not contain molybdenum, so its corrosion resistance is not as good as 316, but it is still very durable in non-extreme environments.

Composition of 304 stainless steel:

- Chromium: 18-20%

- Nickel: 8-10.5%

Advantages:

- More affordable than 316.

- Excellent formability and weldability.

- Suitable for many daily applications.

316 vs. 304 Stainless Steel Sheets

The main difference between 304 and 316 stainless steel is their composition, which directly affects their performance and cost. 316 stainless steel is more resistant to corrosion in harsh environments, especially in environments with salt water or chemical corrosion. 304 stainless steel is more economical and suitable for applications where corrosion resistance is not a high requirement.

Corrosion resistance comparison

In terms of corrosion resistance, 316 stainless steel is undoubtedly superior. Thanks to its higher nickel and molybdenum content, it performs well in high-salt or chemical environments. In contrast, 304 stainless steel performs well in ordinary environments, but may corrode in more severe conditions such as coastal areas or industrial plants.

Application of 316 stainless steel sheets

Due to its excellent corrosion resistance, 316 stainless steel is often used in the following fields:

- Marine applications: ships, docks and offshore platforms.

- Chemical processing: storage tanks and chemical transport equipment.

- Medical equipment: surgical instruments and implants.

- Food processing: equipment with high requirements for cleanliness and durability.

Application of 304 stainless steel sheets

304 stainless steel is suitable for less corrosive environments. Common applications include:

- Home appliances: sinks, stoves and refrigerators.

- Automotive industry: decorative parts and exhaust components.

- Construction: structural and architectural applications such as railings and facades.

- Food and beverage industry: brewing, dairy and food processing equipment.

How to choose 316 vs. 304 stainless steel

When choosing between 316 and 304 stainless steel sheets, the following factors should be considered:

- Environment: If the material is exposed to harsh environments, such as seawater or chemicals, it is recommended to choose 316L stainless steel sheets.

- Budget: If corrosion resistance is not required, 304 stainless steel is more cost-effective.

- Durability: If long-term durability is important, 316 stainless steel is worth investing in even if it is more expensive, because stainless steel plates are also very popular among the public during use.

Common questions about stainless steel plate prices

1. Why is 316 stainless steel more expensive than 304?

316 stainless steel is more expensive because it contains molybdenum, which provides stronger corrosion resistance, especially in marine and industrial environments.

2. Can 304 stainless steel be used in coastal environments?

While 304 can be used, it may not last as long as 316 due to its weaker resistance to chloride corrosion.

3. How does the thickness of stainless steel sheets affect its price?

Thicker stainless steel sheets require more material, resulting in a higher price. The cost increases proportionally with the thickness of the plate.

4. Can I use 304 stainless steel in high temperature applications?

Yes, 304 stainless steel performs well in high temperature environments, but for extreme temperatures, 316 stainless steel is more resistant to scaling and high temperature corrosion.