Embossed stainless steel plates are becoming increasingly popular in modern architecture and design. Their unique combination of durability, aesthetics, and versatility makes them a go-to material for both residential and commercial projects. Whether used in exterior facades, interior design elements, or even custom furniture, these plates offer a range of benefits that appeal to designers, architects, and homeowners alike.

In this comprehensive guide, we’ll explore what embossed stainless steel plates are, the differences between common stainless steel types like 201 and 304, their key applications, and much more. By the end of this article, you’ll have a solid understanding of why embossed stainless steel is such a timeless and valuable material.

Table of Contents

- What is Embossed Stainless Steel?

- 201 vs. 304 Embossed Stainless Steel: What’s the Difference?

- Key Benefits of Embossed Stainless Steel Plates

- Embossed Stainless Steel vs. Stamped Stainless Steel: Key Differences

- 304 Stainless Steel in Moisture-Prone Areas

- Latest Trends in Embossed Stainless Steel Design

- Installation and Maintenance Tips

- FAQs: Common Questions About Embossed Stainless Steel

- What is the difference between 201 and 304 stainless steel?

- Is embossed stainless steel suitable for outdoor use?

- Can I customize the pattern on an embossed stainless steel plate?

- How do I maintain embossed stainless steel in high-traffic areas?

- What is the difference between embossed and stamped stainless steel?

- Is embossed stainless steel expensive?

What is Embossed Stainless Steel?

Embossed stainless steel plates is a type of metal plate that has been processed to include raised or recessed patterns on its surface. These patterns are created through an embossing process, where a stainless steel sheet is passed through rollers or dies that imprint the desired texture. This process not only enhances the visual appeal of the steel but also adds functional benefits, such as increased grip or slip resistance in certain applications.

The embossed designs can vary from simple geometric shapes to complex, custom patterns. This flexibility makes embossed stainless steel a popular choice for designers looking to add a touch of elegance to their projects.

201 vs. 304 Embossed Stainless Steel: What’s the Difference?

One of the most common questions about embossed stainless steel is the difference between the 201 and 304 grades. Both of these are widely used in the production of stainless steel, but they have some key differences that affect their performance and ideal use cases.

201 Stainless Steel

201 stainless steel is known for being more affordable than 304 stainless steel. This is because it contains higher levels of manganese and lower levels of nickel. While this makes it cheaper to produce, it also makes 201 stainless steel less resistant to corrosion, particularly in environments with high moisture or salt exposure. It is best suited for interior applications where it won’t be exposed to harsh environmental conditions.

304 Stainless Steel

304 stainless steel, on the other hand, is considered a higher-quality option. It has a higher chromium and nickel content, making it more resistant to rust and corrosion. This makes 304 stainless steel the preferred choice for outdoor applications or in areas exposed to moisture, such as bathrooms, kitchens, or outdoor facades. While it may cost more upfront, the long-term benefits often outweigh the initial price difference.

Which Should You Choose?

If you’re working on an interior project with minimal exposure to moisture or corrosive substances, 201 stainless steel is a cost-effective option. However, for exterior projects or high-moisture environments, 304 stainless steel is the better choice due to its superior corrosion resistance.

Key Benefits of Embossed Stainless Steel Plates

There are several reasons why embossed stainless steel plates has become a favorite material for designers and builders alike. Let’s explore some of the key benefits:

Durability and Resistance

Stainless steel, in general, is highly durable and resistant to corrosion, heat, and wear. Embossing the steel enhances these properties by adding texture and depth to the surface, making it even more robust. This makes embossed stainless steel ideal for high-traffic areas where the material needs to withstand daily use without showing signs of wear.

Visual Appeal

One of the biggest advantages of embossed stainless steel plates is its aesthetic flexibility. Whether you’re looking for a sleek, modern look or something more traditional, embossed stainless steel can be customized to match almost any design style. The variety of available textures—from simple linear designs to more intricate patterns—means that embossed steel can add a unique, eye-catching element to any space.

Low Maintenance

Stainless steel is non-porous, meaning it doesn’t absorb dirt, grime, or bacteria. This makes it incredibly easy to clean and maintain. All you need is a soft cloth, mild soap, and water to keep it looking new. This makes embossed stainless steel a practical choice for places like kitchens, bathrooms, and public spaces where hygiene is important.

Cost Efficiency Over Time

While embossed stainless steel may come with a higher upfront cost compared to other materials like wood or plastic, it’s a smart long-term investment. Its durability and low maintenance requirements mean you won’t have to worry about frequent repairs or replacements, making it cost-effective over time.

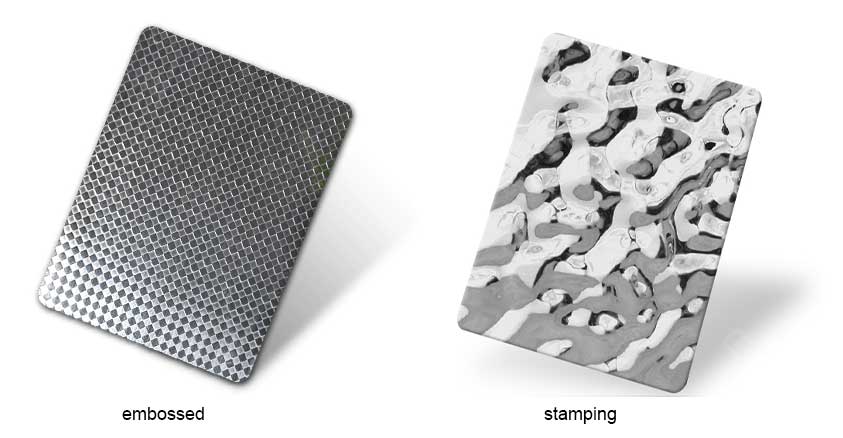

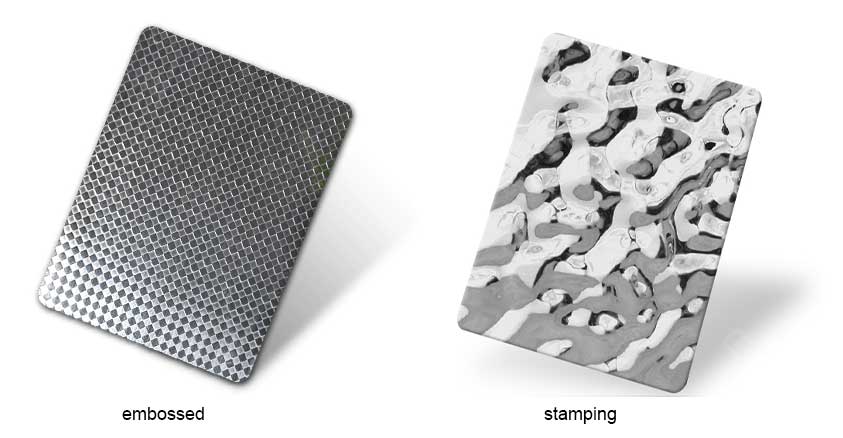

Embossed Stainless Steel vs. Stamped Stainless Steel: Key Differences

Embossed stainless steel plates is produced through a process known as roll embossing. In this method, stainless steel coils are passed through a machine that imprints a consistent pattern or texture onto the surface. The key advantage of embossing is that the shapes and patterns created on the steel surface remain stable and undistorted, even after the rolling process. This makes embossed stainless steel ideal for applications requiring uniform texture, such as decorative wall panels, elevator interiors, and other aesthetic surfaces.

In contrast, stamped stainless steel is created using sheet metal that is shaped by pressing or punching the steel with heavy-duty stamping machines. This process creates raised or recessed patterns on the surface of the metal, often resulting in a more pronounced, uneven texture. Examples of stamped stainless steel patterns include water ripple, honeycomb, diamond plate, and anti-slip surfaces. These patterns are typically deeper and more textured compared to embossed designs and are often used for industrial or functional applications, such as flooring or safety panels, where grip and durability are essential.

In summary, embossing is best suited for creating smooth, consistent textures over large areas, while stamping is ideal for producing deeper, more defined patterns that serve both functional and decorative purposes.

304 Stainless Steel in Moisture-Prone Areas

304 stainless steel is particularly well-suited for areas that are prone to moisture or humidity, such as kitchens, bathrooms, and outdoor spaces. Its high chromium content makes it resistant to rust and corrosion, which is essential in wet environments.

Why Choose 304 for Wet Areas?

If you’re designing a space that will regularly be exposed to water, steam, or humidity, 304 stainless steel is the way to go. Unlike materials like wood or iron, 304 stainless steel won’t warp, rust, or degrade over time, making it a long-lasting solution for moisture-prone areas.

Latest Trends in Embossed Stainless Steel Design

Embossed stainless steel continues to evolve, with new designs and patterns emerging every year. Some of the latest trends in this space include:

Geometric Patterns: Clean, sharp lines and geometric shapes are becoming increasingly popular, especially in modern architectural designs.

Nature-Inspired Motifs: Patterns that mimic natural textures like waves, leaves, or wood grain are in demand for both interior and exterior applications.

Custom Designs: More manufacturers are offering custom embossing options, allowing architects and designers to create one-of-a-kind patterns for their projects.

Installation and Maintenance Tips

Installing embossed stainless steel correctly is crucial to ensuring its longevity and appearance. Here are some tips:

- Surface Preparation: Make sure the surface you’re applying the stainless steel to is clean, smooth, and free of debris to ensure proper adhesion.

- Use Appropriate Fasteners: Depending on the thickness and application, choose the right fasteners to securely install the panels.

- Cleaning: Regular cleaning with a soft cloth and mild detergent is all that’s needed to maintain embossed stainless steel. Avoid abrasive cleaners that may scratch the surface.

FAQs: Common Questions About Embossed Stainless Steel

What is the difference between 201 and 304 stainless steel?

201 is more affordable but less resistant to corrosion. 304 is more expensive but much more durable in wet or outdoor environments.

Is embossed stainless steel suitable for outdoor use?

Yes, especially 304-grade stainless steel, which is highly resistant to weather and corrosion.

Can I customize the pattern on an embossed stainless steel plate?

Yes, many manufacturers offer custom designs to fit your specific needs.

How do I maintain embossed stainless steel in high-traffic areas?

Regular cleaning with a mild detergent and water will keep it in excellent condition.

What is the difference between embossed and stamped stainless steel?

Embossing creates raised or recessed patterns, while stamping involves cutting shapes into the steel.

Is embossed stainless steel expensive?

While it can be more expensive than some materials, its durability and low maintenance make it a cost-effective choice in the long run.