Stainless steel decorative sheets have evolved into one of the most versatile and sought-after materials across various industries. Known for their sleek appearance, durability, and resistance to corrosion, they are widely used in interior design, architecture, and industrial applications. These sheets offer an aesthetically pleasing alternative to traditional materials while maintaining the core benefits of stainless steel, such as strength and longevity.

Table of Contents

- 1. What Are Stainless Steel Decorative Sheets?

- 2. The History and Evolution of Stainless Steel Decorative Sheets

- 3. Types of Stainless Steel Decorative Sheets

- 4. The Manufacturing Process

- 5. Applications of Stainless Steel Decorative Sheets

- 6. Benefits of Stainless Steel Decorative Sheets

- 7. Factors to Consider When Choosing Stainless Steel Decorative Sheets

- 8. Environmental Impact and Sustainability

- 9. Maintenance and Care

- 10. Future Trends in Stainless Steel Decorative Sheets

- 11. Frequently Asked Questions (FAQs)

- 1. What is the difference between 304 and 316 stainless steel?

- 2. How durable are stainless steel decorative sheets?

- 3. Can stainless steel decorative sheets be used outdoors?

- 4. How are stainless steel decorative sheets installed?

- 5. Are stainless steel decorative sheets environmentally friendly?

- 6. Can I customize the design of stainless steel decorative sheets?

- 12. Conclusion

1. What Are Stainless Steel Decorative Sheets?

Stainless steel decorative sheets are specialized stainless steel products designed to combine both aesthetic appeal and functional durability. Unlike regular stainless steel used for industrial or structural purposes, decorative sheets are crafted with a focus on visual beauty. They come in a wide variety of finishes, patterns, and textures, making them highly suitable for both residential and commercial applications.

These sheets can be used for wall cladding, furniture accents, kitchen backsplashes, and many other creative projects. Their adaptability to different design styles, whether it’s minimalist, modern, or industrial, has made them a preferred material among architects, interior designers, and builders.

2. The History and Evolution of Stainless Steel Decorative Sheets

Stainless steel was first invented in 1913 by British metallurgist Harry Brearley, who discovered that adding chromium to steel made it resistant to rust and corrosion. Initially, stainless steel was used for cutlery and surgical instruments, but its unique properties soon saw it adopted in construction, automotive, and many other industries.

Decorative stainless steel sheets were introduced much later. As architectural styles evolved, designers sought materials that were not only durable but also visually appealing. In the mid-20th century, advancements in surface treatment technologies allowed for the production of stainless steel sheets with intricate designs, textures, and finishes. This opened the door for their use in design-forward applications, such as building facades, interior decor, and luxury products.

Today, stainless steel decorative sheets are a go-to material for designers, offering a perfect combination of functionality and aesthetics.

3. Types of Stainless Steel Decorative Sheets

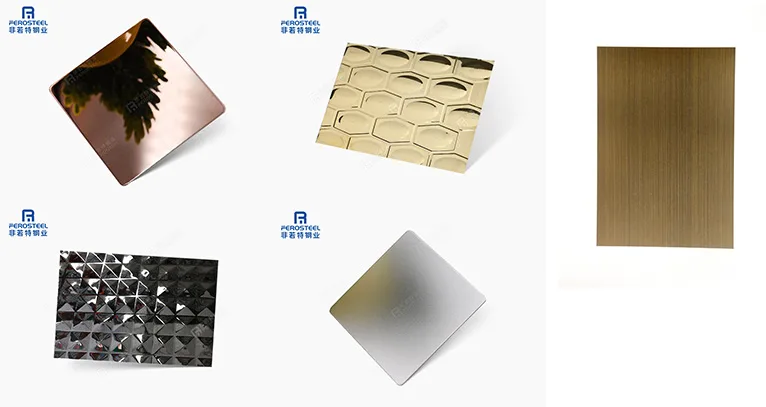

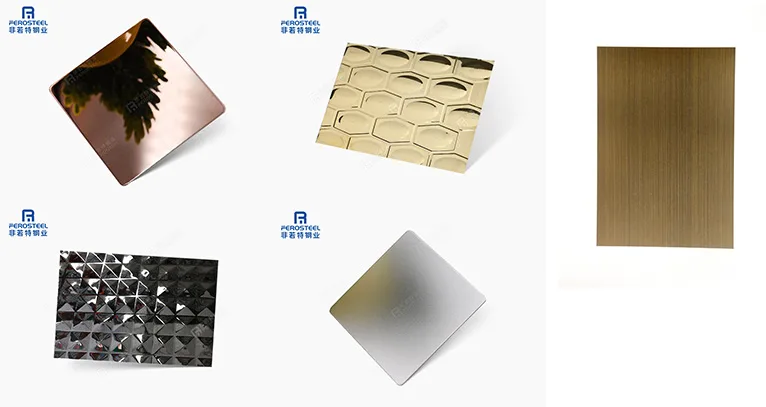

Stainless steel decorative sheets come in several different types, each offering its own unique characteristics. Below are the most commonly used varieties:

3.1 Etched Stainless Steel Sheets

Etched stainless steel sheets are produced using a chemical process that removes material from the surface to create a pattern or texture. The resulting design contrasts with the non-etched areas, giving the sheet a sophisticated, textured appearance. These sheets are ideal for elevator interiors, signage, or decorative wall panels, offering a unique visual element.

3.2 Embossed Stainless Steel Sheets

Embossing involves creating raised designs or patterns on the surface of the sheet, adding both aesthetic value and functionality. Embossed stainless steel sheets are commonly used in areas where slip resistance is needed, such as flooring, or where a tactile feel is desired, such as in handrails and public spaces.

3.3 PVD Coated Stainless Steel Sheets

Physical Vapor Deposition (PVD) coating is a method that deposits a thin, durable layer of metal (such as titanium) onto the surface of stainless steel. This gives the sheet a colorful and hard-wearing finish, available in gold, bronze, black, and even rainbow hues. PVD-coated sheets are popular in luxury interiors and high-end facades, adding a touch of elegance and color to any project.

3.4 Mirror-Finished Stainless Steel Sheets

Mirror-finished stainless steel sheets are polished to a highly reflective surface, offering a sleek and modern look. These sheets are often used in architecture to create a sense of openness by reflecting light and the surrounding environment. They are commonly seen in decorative walls, elevators, and furniture.

3.5 Brushed Stainless Steel Sheets

Brushed stainless steel sheets feature a matte finish with subtle linear scratches, created through a sanding process. This finish is particularly popular for applications that need to resist fingerprints and smudges, such as kitchen appliances, signage, and elevator interiors. The brushed texture adds a modern, understated elegance.

4. The Manufacturing Process

The production of stainless steel decorative sheets involves several key steps, starting with raw material selection and ending with the final surface finish. Here’s an overview of the process:

4.1 Material Selection

Stainless steel is made by melting iron ore and adding elements such as chromium, nickel, and molybdenum. Chromium is what makes stainless steel resistant to corrosion, while nickel and molybdenum enhance its strength and flexibility. Different grades of stainless steel are used depending on the application, with 304 and 316 being the most common.

4.2 Surface Treatment Techniques

After the stainless steel is formed into sheets, various surface treatment processes are applied to create decorative finishes. These treatments include polishing, brushing, etching, and coating. For example, mirror finishes require extensive polishing, while PVD coatings are applied in a vacuum chamber. Each technique produces a distinct aesthetic and functional result, tailored to the needs of the project.

5. Applications of Stainless Steel Decorative Sheets

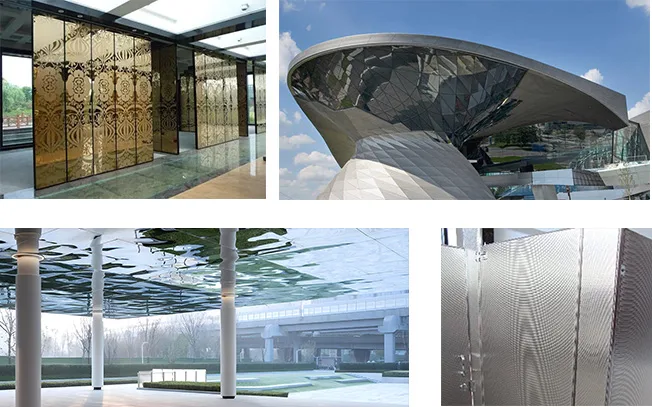

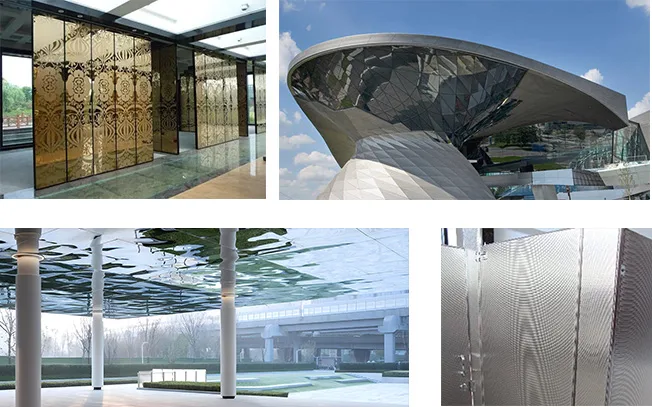

Stainless steel decorative sheets are incredibly versatile and are used in a wide range of applications across various industries. Here are some of the most common uses:

5.1 Interior Design

In interior design, stainless steel decorative sheets are used to create modern, sophisticated environments. They are often applied to walls, ceilings, and room dividers in commercial spaces such as hotels, offices, and retail stores. Their durability and low maintenance make them ideal for high-traffic areas, while their aesthetic appeal enhances the overall design.

5.2 Exterior Cladding and Facades

For exterior cladding, stainless steel decorative sheets provide both aesthetic appeal and protection from the elements. Their corrosion-resistant properties ensure that buildings maintain a sleek appearance over time, even in harsh environments. The reflective nature of mirror-finished sheets can also contribute to energy efficiency by reducing heat absorption in buildings.

5.3 Elevator Panels and Escalators

Due to their resistance to wear and tear, stainless steel decorative sheets are commonly used for elevator interiors and escalator side panels. Brushed or etched finishes not only add a refined look but also help hide fingerprints and smudges, making them practical for high-use areas.

5.4 Kitchen Appliances and Equipment

In both residential and commercial kitchens, stainless steel decorative sheets are used for backsplashes, countertops, and appliance exteriors. Their sleek appearance complements modern kitchen designs, and their resistance to heat, stains, and corrosion makes them a practical choice for high-performance kitchens.

5.5 Signage and Advertising

Stainless steel decorative sheets are often used in custom signage, offering a modern and professional look for logos, plaques, and directional signage. Etched or laser-cut designs can add a high level of detail, making stainless steel a popular choice for businesses and institutions that require durable and eye-catching signage.

6. Benefits of Stainless Steel Decorative Sheets

There are several reasons why stainless steel decorative sheets are so widely used, with their key benefits including:

- Durability: Stainless steel is extremely durable and resistant to corrosion, making it ideal for both indoor and outdoor use.

- Aesthetic Appeal: With a wide range of finishes, patterns, and colors, stainless steel decorative sheets can complement any design style.

- Low Maintenance: Stainless steel is easy to clean and maintain. Most finishes are resistant to fingerprints, smudges, and stains.

- Versatility: Stainless steel decorative sheets are suitable for various applications, from architectural facades to interior design and signage.

- Sustainability: Stainless steel is 100% recyclable, and many decorative sheets are made from recycled materials, making it an environmentally friendly choice.

7. Factors to Consider When Choosing Stainless Steel Decorative Sheets

When selecting stainless steel decorative sheets for a project, several factors should be taken into account:

- Finish: The finish should complement the overall design of your project. For example, a mirror finish creates a sleek, modern look, while a brushed finish provides a more subdued, matte appearance.

- Grade: The grade of stainless steel used affects its resistance to corrosion and its suitability for certain environments. Grade 304 is commonly used for interior applications, while grade 316 is preferred for outdoor use due to its higher corrosion resistance.

- Thickness: Thicker sheets provide more durability, while thinner sheets offer greater flexibility for more intricate designs.

- Application: Consider where the sheet will be used—whether for exterior cladding, interior decor, or signage—as different environments will have different demands.

8. Environmental Impact and Sustainability

Stainless steel is one of the most environmentally sustainable materials available. It is 100% recyclable, and many stainless steel decorative sheets are produced using recycled content. The longevity and durability of stainless steel reduce the need for frequent replacements, further minimizing environmental impact over time.

Additionally, stainless steel production processes have become increasingly efficient, with reduced energy consumption and lower emissions, making it an even more eco-friendly option.

9. Maintenance and Care

Although stainless steel decorative sheets are known for being low-maintenance, regular care can extend their lifespan and keep them looking their best. Here are a few tips:

- Regular Cleaning: Use a soft cloth and a mild detergent to clean the surface. Avoid abrasive cleaners that could scratch the finish.

- Fingerprint and Smudge Removal: For polished or mirror finishes, use a microfiber cloth to remove smudges and fingerprints.

- Corrosion Prevention: While stainless steel is corrosion-resistant, regular cleaning in harsh environments (such as marine settings) can help prevent rust or stains.

- Avoid Harsh Chemicals: Refrain from using bleach or chlorine-based cleaners, as these can damage the surface and compromise its protective coating.

10. Future Trends in Stainless Steel Decorative Sheets

The future of stainless steel decorative sheets is shaped by technological advancements and sustainability trends. Here are a few emerging trends to watch:

- Advanced Surface Treatments: New techniques such as laser etching and 3D printing are expanding the possibilities for stainless steel design. These allow for more intricate and customized patterns and textures.

- Sustainability: With increasing emphasis on eco-friendly building materials, stainless steel is likely to grow in popularity due to its recyclability and long lifespan.

- Color Customization: As PVD coating technology advances, stainless steel decorative sheets are becoming available in a wider variety of colors, making them an increasingly popular choice for luxury and high-end design projects.

11. Frequently Asked Questions (FAQs)

1. What is the difference between 304 and 316 stainless steel?

The main difference is that 316 stainless steel contains molybdenum, which provides greater resistance to corrosion, particularly in marine or harsh environments. While 304 is more commonly used indoors, 316 is preferred for outdoor and industrial applications.

2. How durable are stainless steel decorative sheets?

Stainless steel decorative sheets are highly durable, offering resistance to corrosion, heat, and wear. With proper care, they can last for decades without losing their appeal or functionality.

3. Can stainless steel decorative sheets be used outdoors?

Yes, many stainless steel decorative sheets, especially those made from 316-grade stainless steel, are designed for outdoor use. They are resistant to corrosion and harsh weather, making them ideal for building facades and exterior cladding.

4. How are stainless steel decorative sheets installed?

The installation method depends on the application. They can be mechanically fastened, glued with industrial-strength adhesives, or mounted using specialized cladding systems.

5. Are stainless steel decorative sheets environmentally friendly?

Yes, stainless steel is fully recyclable, and many decorative sheets are made from recycled material. Additionally, their durability and low maintenance requirements make them a sustainable choice for long-term use.

6. Can I customize the design of stainless steel decorative sheets?

Absolutely. Many manufacturers offer custom design options through etching, embossing, and laser cutting techniques, allowing for unique patterns and finishes tailored to specific projects.

12. Conclusion

Stainless steel decorative sheets offer an exceptional combination of aesthetics, durability, and versatility. From sleek modern interiors to durable exterior facades, these sheets can be adapted to a wide range of applications. Their resistance to corrosion, ease of maintenance, and long lifespan make them a practical choice for both residential and commercial use.

As technology continues to evolve, the future of stainless steel decorative sheets promises even greater possibilities for customization and sustainability. Whether you are designing a high-end retail space or adding a modern touch to your home, stainless steel decorative sheets provide a durable and stylish solution that will stand the test of time.