Choosing the right stainless steel is critical for any project, as different types of stainless steel vary in terms of performance, corrosion resistance and cost. Here are some guidelines to help you choose the most appropriate type of stainless steel for your project.

Stainless steel grade

The commonly-used stainless steel grades are 201, 304, and 316/316L. Grade 201 is a basic option with fewer features and is affordable but does not perform well in harsh conditions. In contrast, grade 304 is more suitable for wet environments and offers easier fabrication options such as bending, although it comes at a slightly higher cost. If you require the highest level of durability and resistance to harsh conditions, grade 316 is the premium choice despite its higher price tag. When selecting stainless steel, it is important to consider your specific needs. In most cases, grade 304 provides a balanced combination of strength and cost-effectiveness.

Size and thickness

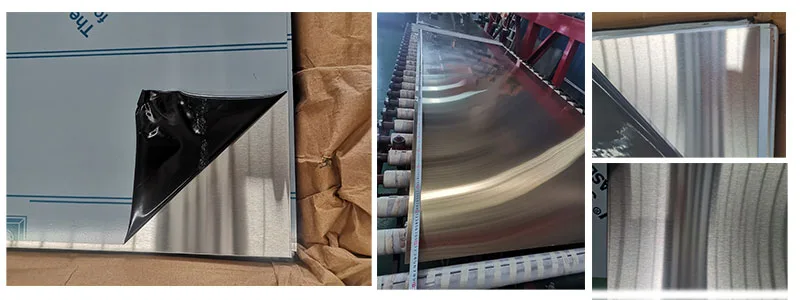

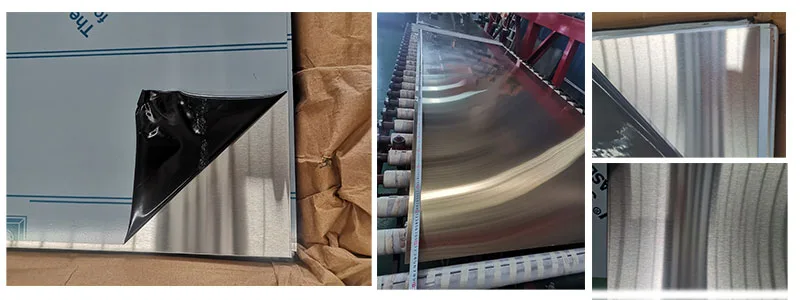

The selection of the thickness for the stainless steel sheet should be based on the structural requirements of the application. Thicker sheets enhance strength and rigidity, while thinner sheets are suitable for decorative purposes without structural roles. The thickness typically ranges from 0.5mm for light-duty applications to 3mm for heavy-duty uses, with a consistent production time across this range.

The standard sizes for stainless steel sheets are 1219x2438mm, 1219x3048mm, 1000x2000mm, and 1500x3000mm. Customization is available for width and length, with a maximum width limit of 1500mm.

Design and aesthetic appeal

Commonly used in modern architecture and home design, stainless steel sheets bring a clean, dry and high-tech feel. Brushed stainless steel and matte stainless steel are often used in industrial style interiors, presenting a rugged, functional aesthetic. Mirror-polished and titanium-plated stainless steel sheets are often used in high-grade places, such as hotel lobbies and lift interiors, to create a sense of luxury and texture. Etching, spraying, hollowing and other processes can create a variety of artistic patterns on the stainless steel plate, making it not only functional, but also has a high artistic ornamental value.

Functionality vs aesthetic

Corrosion resistance

Stainless steel sheet has excellent corrosion resistance and is able to resist corrosion by a wide range of media such as air, water, and acids . This makes it widely used in the chemical industry, food processing, medical equipment and other fields.

Strength and toughness

Stainless steel sheet has high strength and toughness, able to withstand greater pressure and impact, suitable for building structures, bridges, vehicle manufacturing and other areas that require high-strength materials.

High temperature resistance

Stainless steel can still maintain good physical properties and chemical stability in high temperature environment, suitable for boilers, heat exchangers, gas turbines and other high temperature equipment.

Budget

There are different types of stainless steel, such as 304, 316 and 430. The price of different types of stainless steel varies greatly. Different surface treatment processes, such as mirror polishing, brushing, sandblasting, etching, etc., will affect the price of stainless steel. Complex surface treatment usually increases the cost. The thickness and size of the stainless steel sheet directly affects the price. Thicker plates and larger sizes are more expensive.

Maintenance and durability

Stainless steel sheet has high strength and toughness, able to withstand high pressure and impact forces, and is not easily deformed or fractured. Especially in construction and industrial applications, its structural strength is very important. Clean with mild soapy water or specialized stainless steel cleaners, avoiding those containing bleach or abrasive cleaning agents. When cleaning, wipe gently with a soft cloth or sponge to avoid scratching the surface.

Choosing the right decorative stainless steel sheet requires consideration of several factors, including material type, finish, thickness, size, application environment and budget. By comprehensively considering the above factors, you can choose the decorative stainless steel sheet that best suits the needs of your project and achieve the desired decorative effect and service life.