Water ripple stainless steel sheets are becoming an increasingly popular choice in modern design due to their unique texture and reflective properties. They bring a touch of elegance and sophistication to both interior and exterior spaces, making them ideal for a range of applications. In this guide, we will explore every aspect of water ripple stainless steel sheets, including their origins, uses, and benefits.

Table of Contents

- 1. Introduction to Water Ripple Stainless Steel Sheets

- 2. History and Development

- 3. Materials and Composition

- 4. Manufacturing Technology

- 5. Types and variations

- 6. water ripple stainless steel in indoor and outdoor design

- 7. Comparison with other decorative materials

- 8. Customization options

- 9. Cost and budget

- 10. Choosing a Supplier

- 11. Frequently Asked Questions

- Q1: How are water ripple stainless steel sheets made?

- Q2: Can these sheets be used in high-moisture areas?

- Q3: Are custom designs possible?

- Q4: How do I maintain the sheets’ reflective quality?

- Q5: What are the environmental benefits of using stainless steel?

- Q6: How do I choose the right thickness for my project?

- 12. Conclusion

1. Introduction to Water Ripple Stainless Steel Sheets

Water ripple stainless steel sheets are decorative panels with a surface texture that mimics the appearance of rippling water. These sheets are made from high-quality stainless steel, embossed with patterns that create a dynamic, wavy effect. Their reflective properties make them a popular choice for adding depth and light to spaces, making them particularly suitable for luxury interiors and eye-catching architectural designs.

2. History and Development

The concept of textured metal surfaces is hundreds of years old, however, corrugated stainless steel sheets as a modern decorative material have developed with the advancement of manufacturing technology. At first, this material was mainly used for industrial purposes, but its unique texture and reflective effects soon attracted the attention of designers. Today, water ripple stainless steel sheets have become a fashionable element in architectural and interior design.

3. Materials and Composition

Ripple stainless steel sheets are usually made of high-quality stainless steel materials, such as 304 or 316 grade stainless steel. These materials are known for their corrosion resistance, high strength and easy processing, ensuring that corrugated stainless steel sheets can maintain their beauty and functionality in a variety of environments. In addition to the basic stainless steel material, the surface of Ripple stainless steel sheets may also be plated or otherwise treated to enhance its color and reflective effects.

4. Manufacturing Technology

The manufacturing process of water ripple stainless steel sheets involves a variety of precision processes to ensure its unique appearance and durability. The main manufacturing technologies include:

Stamping: This is the core process of water ripple stainless steel sheet manufacturing. By using a stamping die, the stainless steel sheet is pressed into a three-dimensional effect with a corrugated pattern. High-precision stamping equipment and molds ensure the consistency and beauty of the corrugation.

Mirror treatment: After stamping, the plate is usually mirror-polished to enhance the gloss of its surface. This treatment makes the surface of the plate smoother, improves its reflection effect, and makes the visual effect of the water ripple more prominent.

Color plating: In order to increase the decorative effect, the water ripple stainless steel plate can be PVD (physical vapor deposition) plated. This process forms a thin film on the surface of the plate, providing a variety of color options, such as gold, rose gold, black titanium and bronze. This not only gives the plate a rich color, but also improves its wear resistance and corrosion resistance.

5. Types and variations

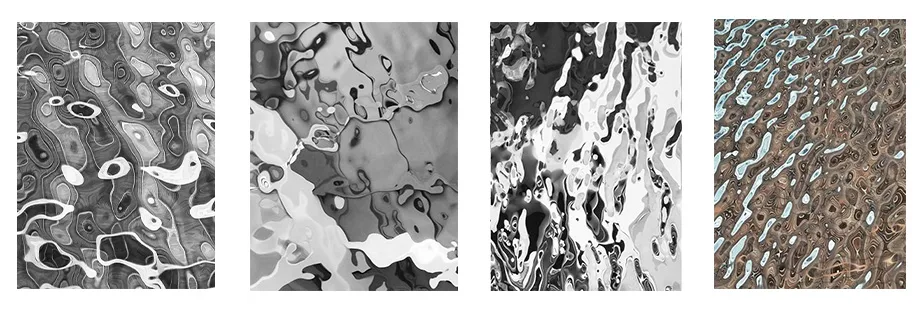

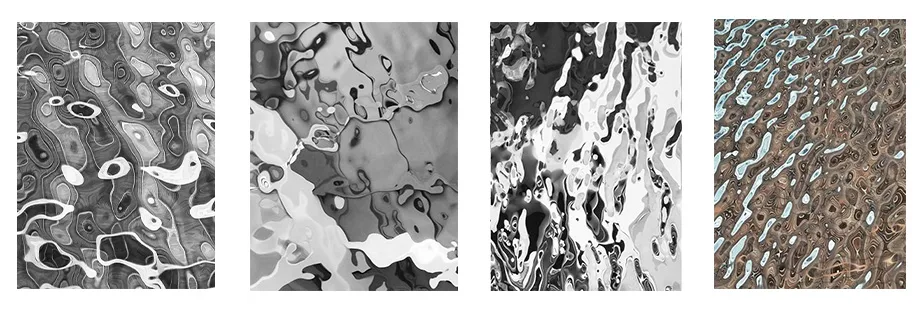

Water ripple stainless steel sheets have a variety of types and variations to meet different design needs:

Pattern: The optional water ripple patterns range from delicate microwaves to obvious ripples, each with a unique visual effect.

Surface treatment: Including polishing, brushing, matte and other surface treatment methods. The polished surface is highly reflective, while the brushed surface presents a soft luster.

Color: Through PVD coating technology, ripple stainless steel plates can present a variety of colors, from classic silver to fashionable gold, rose gold, and even customized colors to meet different aesthetic needs.

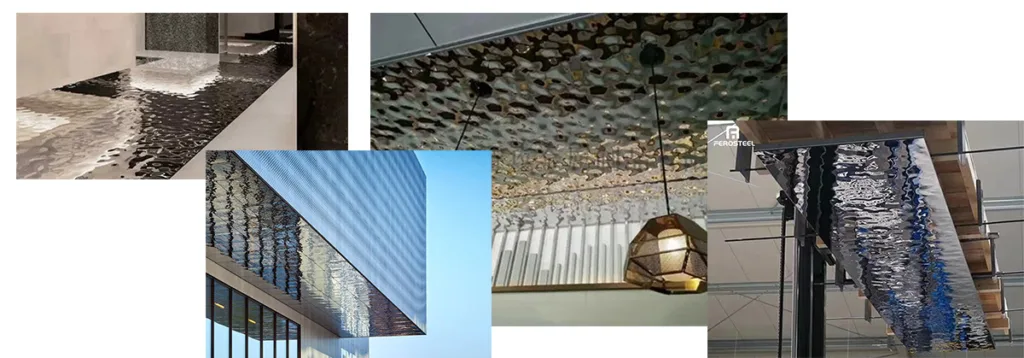

6. water ripple stainless steel in indoor and outdoor design

Water Ripple stainless steel plates are widely used in indoor and outdoor design due to their unique texture and gloss. Its diverse uses can meet the needs of different environments and styles, not only enhancing the visual effect of the space, but also increasing the texture and quality.

Application in interior design

- Wall decoration: Water ripple stainless steel sheets are often used for wall decoration in spaces such as halls, corridors and living rooms. Its unique ripple effect can enhance the layering of the space, reflect light, increase brightness, and make the entire space appear more modern and artistic.

- Furniture and cabinets: These stainless steel plates can be used as furniture surfaces, such as tabletops, cabinet doors, and bar counters. The ripple effect adds a unique touch and visual effect to the furniture, making ordinary furniture more design-oriented.

- Ceilings and suspended ceilings: Water ripple sheets can be used for ceiling or suspended ceiling decoration, creating a sense of space expansion through its reflective properties, making the indoor environment appear more spacious.

- Lighting and lighting fixtures: Due to its mirror effect, water ripple stainless steel sheets are very suitable as materials for lighting and lighting fixtures. It can reflect light, produce soft light and shadow effects, and create a luxurious and warm atmosphere.

Application in outdoor design

- Building facades: Water ripple stainless steel sheets can be used as decorative sheets in building exterior walls and facade decoration. Its weather resistance and corrosion resistance make it an ideal choice for outdoor applications, while the ripple effect of reflecting light adds a modern and visual impact to the appearance of the building.

- Garden landscape: Water corrugated stainless steel sheets can be used in garden design, such as water feature walls, flower bed decorations, and decorative screens beside walkways. Its ripple effect complements the natural environment and can create a dynamic visual experience.

- Public art installations: In public spaces, this material is often used for sculptures and art installations. Its unique light reflection characteristics make the work present a variety of effects under different light conditions, interact with the surrounding environment, and attract the audience’s attention.

7. Comparison with other decorative materials

Water ripple stainless steel plate has its unique advantages in decorative materials:

Comparison with glass: Although glass has a reflective effec, water ripple stainless steel sheets is more durable and not easy to break. At the same time, it can also provide a mirror-like reflection effect, but more modern and three-dimensional.

Comparison with aluminum: Aluminum plates are generally lighter, but not as durable as stainless steel. Water ripple stainless steel sheets are superior to aluminum in strength and corrosion resistance, and provide a richer range of surface treatments and color options.

Comparison with copper: Copper plates have a unique color, but are easily oxidized and tarnished. In contrast, water ripple stainless steel plates maintain their glossiness and will not discolor due to oxidation, while providing a more modern appearance.

8. Customization options

Water ripple stainless steel plates offer a variety of customization options to meet specific design needs:

Customized patterns: Unique ripple patterns can be designed according to customer needs, giving the project a unique personality.

Color options: Through PVD coating technology, the plates can present a variety of customized colors, including gold, rose gold, black titanium, etc., to meet different aesthetic needs.

Surface treatment: A variety of surface treatment options are available, such as brushed, mirror, matte, etc., to increase design flexibility.

9. Cost and budget

The cost of water ripple stainless steel plates depends on a variety of factors, including material quality, surface treatment, size and customization requirements.

Material quality: Using higher grades of stainless steel materials (such as grade 316) usually increases costs, but also provides better corrosion resistance and durability.

Surface treatment and customization: Special surface treatments and customized colors and patterns may increase costs, but these investments can bring unique aesthetic value to the project.

Size and thickness: Larger and thicker plates are usually more expensive, but they offer more advantages in durability and strength.

10. Choosing a Supplier

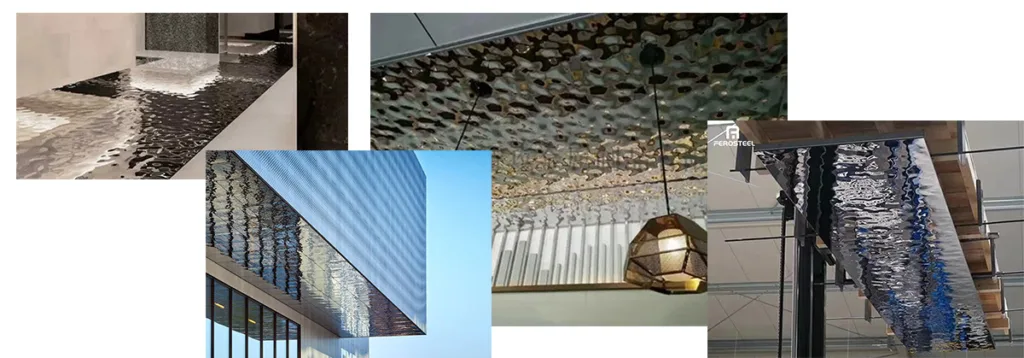

Selecting a reliable supplier for water ripple stainless steel sheets is crucial to ensure the quality and performance of your project. We recommend Ferosteel, a leading supplier known for high-quality stainless steel decorative panels and excellent service.

Ferosteel specializes in providing premium water ripple stainless steel sheets and other metal decorative materials to customers worldwide. With a focus on quality, we offer a wide range of innovative designs and surface treatments to meet diverse customer needs. Our water ripple stainless steel sheets are crafted from top-grade 304 and 316 stainless steel and undergo rigorous manufacturing processes and quality control to ensure each sheet meets the highest standards.

Why Choose Ferosteel as Your Supplier?

- Extensive Experience and Expertise: Ferosteel has years of experience in the stainless steel decorative sheet industry, understanding both industry standards and customer needs. Our professional team is dedicated to delivering the highest quality products and services.

- High-Quality Products: Our water ripple stainless steel sheets are produced using advanced manufacturing techniques and premium materials, ensuring outstanding durability and aesthetic appeal. We offer a variety of surface treatments and color options to cater to different project requirements.

- Customization Services: Ferosteel provides customization services based on clients’ specific needs, including custom sizes, patterns, and colors. We work closely with our customers to ensure that the products align perfectly with their design concepts and functional requirements.

- Global Supply: With an extensive global logistics network, we can deliver products quickly and efficiently to locations around the world, ensuring your project’s timely progression.

Recommended Supplier Link: Ferosteel

Visit our official website to explore our complete product range, including detailed information and application examples of various water ripple stainless steel sheets. We also offer professional customer support to answer any questions you may have about our products and help you choose the best materials for your project.

Choosing Ferosteel as your supplier for water ripple stainless steel sheets ensures the highest quality and design impact for your project. Whether for interior decoration or architectural exteriors, we are committed to providing you with the finest materials and services to add unique style and value to your project.

11. Frequently Asked Questions

Q1: How are water ripple stainless steel sheets made?

A1: They are made through processes like embossing, etching, and coating to create the textured, reflective surface.

Q2: Can these sheets be used in high-moisture areas?

A2: Yes, stainless steel’s corrosion resistance makes it suitable for areas like bathrooms and kitchens.

Q3: Are custom designs possible?

A3: Yes, many manufacturers offer customization options for patterns, colors, and finishes.

Q4: How do I maintain the sheets’ reflective quality?

A4: Regular cleaning with non-abrasive cleaners and soft cloths will help maintain the reflective surface.

Q5: What are the environmental benefits of using stainless steel?

A5: Stainless steel is fully recyclable and has a long lifespan, reducing the need for frequent replacements.

Q6: How do I choose the right thickness for my project?

A6: The thickness depends on the application. Thicker sheets are better for high-traffic or heavy-use areas.

12. Conclusion

Water ripple stainless steel sheets offer a unique blend of aesthetic appeal, durability, and versatility, making them an excellent choice for a wide range of design applications. Whether used in interiors or exteriors, their distinctive texture and reflective properties can transform any space. With proper installation and care, they provide a long-lasting, environmentally friendly option that adds value and beauty to any project.