1. Discoloration and decolorization of stainless steel color plates

The discoloration and discoloration of color stainless steel sheets are mainly caused by improper selection of paint. Indoors and outdoors coated with stainless steel colored sheets. Two different coatings determine the application of stainless steel color plates. Generally, ordinary paint, polyester powder coating and polyester paint are used indoors. These three kinds of coatings all cannot adapt to harsh outdoor natural environment. If it is used outdoors, the service life of the stainless steel color plate will naturally be shortened, which will accelerate aging and cause discoloration.

2. Deformation of color stainless steel sheet

There are many reasons for the deformation of the color stainless steel sheet. This problem may be caused by the stainless steel plate itself. Processing stainless steel colored plates requires high-strength, high-quality plates in order to produce good color stainless steel sheets. Improper selection of plates, rain or sun and rain during use will inevitably lead to deformation of stainless steel color plates. Another reason for the deformation may be that the stainless steel color plate is not well protected during transportation, resulting in deformation of the stainless steel color plate.

3. The assembly gap of the stainless steel color plate is large, which is not suitable for

Because the stainless steel color plate is measured by the designer of the stainless steel color plate manufacturer on site, and then the overall installation design of the stainless steel color plate is carried out, so the on-site measurement of the stainless steel color plate is very important. If the size is wrong, there will be a large gap or improper installation in the stainless steel color plate project.

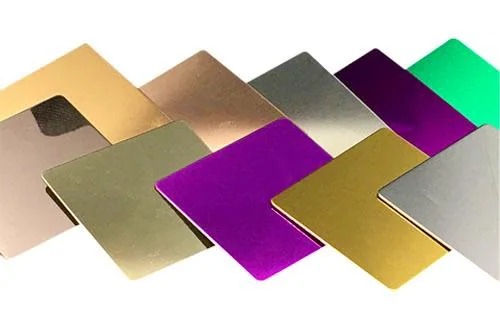

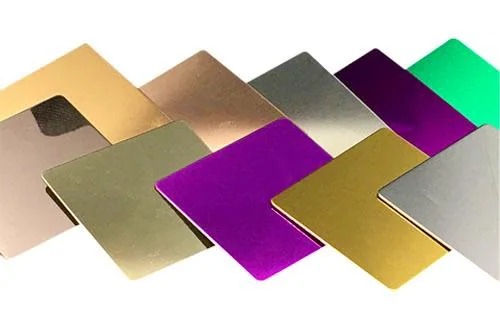

Installing color stainless steel sheets adds a touch of sophistication and vibrance to any space. However, it’s essential to be aware of potential installation challenges to ensure a flawless and long-lasting result. In this comprehensive guide, we provide expert solutions and tips to overcome common issues encountered during the installation process. From addressing alignment problems to tackling adhesive concerns, we equip you with the knowledge and techniques needed to achieve a professional finish with stainless steel color plates.

- Understanding the Importance of Proper Alignment

- Ensuring Adequate Surface Preparation for Optimal Adhesion

- Selecting the Right Adhesive: A Crucial Step for Secure Attachment

- Mitigating Potential Damage during Handling and Installation

- Properly Sealing Joints and Edges for Enhanced Durability

About Color Stainless Steel Sheets FAQs

Are color stainless steel sheets environmentally friendly?

Yes, color stainless steel sheets are considered environmentally friendly. Stainless steel is a recyclable material, and the color coatings used are often formulated to be eco-friendly and low in volatile organic compounds (VOCs). Choosing color stainless steel sheets not only adds aesthetic value to your space but also contributes to sustainable design and construction practices.

How do I maintain the appearance of color stainless steel sheets?

To maintain the appearance of color stainless steel sheets, regular cleaning and proper maintenance are essential. Use a mild detergent or stainless steel cleaner with a soft cloth or sponge to remove dirt or smudges. Avoid using abrasive materials or harsh chemicals that could damage the color coating. Regularly inspect the sheets for any signs of wear or damage and address them promptly to ensure long-lasting beauty.

Can I request a custom color for my stainless steel sheets?

Yes, many suppliers offer custom color options for stainless steel sheets. Whether you want to match a specific color scheme or create a unique design statement, you can work with a reputable supplier to discuss your requirements and explore the possibilities of custom color matching. Keep in mind that custom colors may have specific order quantities or lead times, so it’s best to inquire in advance.