Stainless steel dimple sheets may not be the most well-known product in the world of industrial materials, but they certainly pack a punch when it comes to versatility and utility. These innovative sheets have found their way into a wide range of applications, from enhancing heat transfer to improving the durability of equipment. In this blog post, we’ll delve into the world of stainless steel dimple sheets, exploring their value, applications, and the industries that benefit from their use.

What Are Stainless Steel Dimple Sheets?

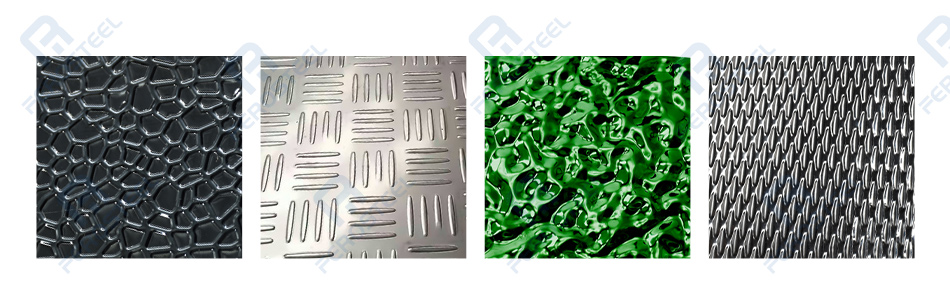

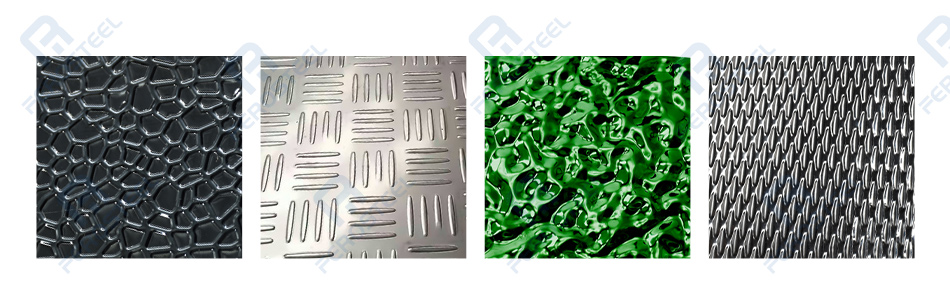

Before we dive into their applications, let’s briefly understand what stainless steel dimple sheets are. Dimple sheets are thin, flat pieces of stainless steel that have a pattern of dimples or indentations on one or both sides. These dimples create small raised areas on the sheet’s surface, altering its physical properties and making it ideal for certain applications.

Applications of Stainless Steel Dimple Sheets

Heat Exchangers: One of the most common applications of dimple sheets is in heat exchangers. The dimples on the sheets create turbulence in the flow of liquids or gases, which significantly improves heat transfer efficiency. This makes them indispensable in industries such as HVAC, petrochemical, and food processing.

Food and Beverage Industry: Stainless steel dimple sheets are widely used in the food and beverage industry, particularly in the production of heat exchangers for pasteurization and sterilization processes. Their corrosion resistance and hygienic properties make them an excellent choice for ensuring product safety and quality.

Aerospace and Automotive: In the aerospace and automotive sectors, dimple sheets find applications in radiators and oil coolers, where efficient heat dissipation is crucial to engine performance and longevity.

Energy Sector: Dimple sheets are used in the energy sector for applications like cooling systems in power plants, where the ability to transfer heat efficiently is essential for maintaining equipment reliability.

Water Treatment: The water treatment industry utilizes dimple sheets in heat exchangers and tanks for water purification processes.

Advantages of Stainless Steel Dimple Sheets

Enhanced Heat Transfer: The primary advantage of dimple sheets is their ability to improve heat transfer. The dimples disrupt laminar flow, promoting better mixing and heat exchange, resulting in higher efficiency and lower energy consumption.

Corrosion Resistance: Stainless steel itself is known for its resistance to corrosion, making dimple sheets suitable for applications where exposure to moisture or chemicals is common.

Durability: These sheets are built to last. Their sturdy construction ensures they can withstand harsh industrial environments and temperature extremes.

Hygiene and Cleanability: In industries where hygiene is paramount, such as food processing, dimple sheets are easy to clean and maintain, reducing the risk of contamination.

Customization: Dimple sheets can be tailored to meet specific requirements, with various patterns and configurations available to suit different applications.

Conclusion

Stainless steel dimple sheets are a versatile and valuable material that plays a critical role in various industries. Their ability to enhance heat transfer efficiency, coupled with their durability and corrosion resistance, makes them a sought-after choice for engineers and manufacturers.

Whether you’re in the food industry, aerospace, or energy sector, these sheets are likely contributing to the success and reliability of your operations. As technology continues to advance, stainless steel dimple sheets are sure to find even more innovative applications in the future.