Our extensive selection of mirror polish includes No.8, No.10, and No.12 finishes. We also offer a wide range of colors, including gold, rose gold, champagne, black, blue, green, violet, and copper, providing numerous customization options to suit your design needs.

Ⅰ.Production Process of Mirror Polished Stainless Steel Sheets

Raw Material Preparation

Material Selection: Choose high-quality stainless steel coils, commonly using materials like 304 or 316.

Surface Inspection: Perform an initial inspection of the stainless steel coil surface to ensure there are no obvious defects, such as scratches or stains.

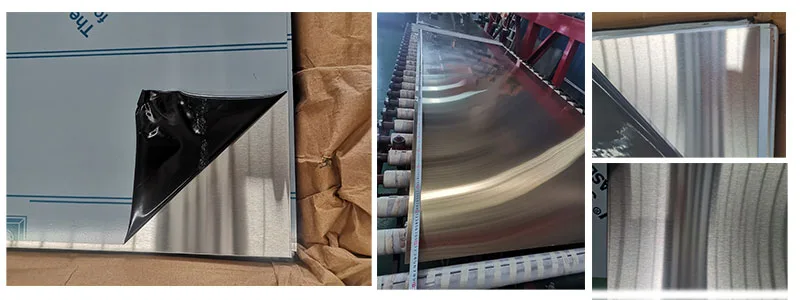

Uncoiling and Cutting

Uncoiling: Use an uncoiling machine to flatten the stainless steel coils into sheets.

Cutting: Cut the sheets to the required sizes for subsequent processing.

Polishing

Coarse Polishing: Use a coarse polishing machine and polishing paste for initial polishing to remove fine scratches.

Fine Polishing: Use a fine polishing machine and high-precision polishing paste for final polishing to achieve a mirror finish.

Cleaning and Drying

Cleaning: Use cleaning equipment to remove any remaining polishing paste and other impurities from the polishing process.

Drying: Use hot air drying equipment to quickly dry the cleaned stainless steel sheets, avoiding water stains affecting surface quality.

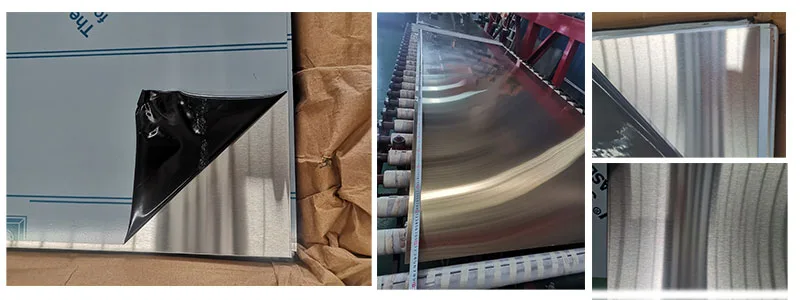

Protective Film Application

Film Applicator: Use a film applicator to cover the surface of the mirror-polished stainless steel sheets with a protective film to prevent scratches or contamination during transportation and installation.

Quality Inspection

Visual Inspection: Perform a visual inspection to ensure the surface of the mirror-polished stainless steel sheets is free of scratches, stains, and other defects.

Precision Inspection: Use professional equipment to check the flatness, gloss, and other quality parameters of the sheets to ensure they meet the standards.

Packaging and Storage

Packaging: Pack the qualified mirror-polished stainless steel sheets with protective materials to prevent damage during transportation.

Storage: Store the packed stainless steel sheets in a dry, ventilated warehouse to avoid moisture and contamination.

Through this process, high-quality, smooth, and mirror-like stainless steel sheets are produced.

Ⅱ.Product information

Grade : 304/316/430, etc

Material : stainless steel

Origin : China

MOQ : 30 sheets

Size : 1000mm*2000mm, 1219mm*2438mm, 1219mm*3048mm, 1500mm*3000mm, etc

Custom available : Available

Finishing : Mirror finish, PVD color coating is available

Ⅲ. Application Scenarios for Mirror Polished Stainless Steel Sheets

Architectural Decoration

Exterior Walls and Curtain Walls: Mirror polished stainless steel sheets are widely used for building exterior walls and curtain walls due to their high gloss and modern appearance, enhancing the fashion and grandeur of the building.

Lobbies and Entrances: Using mirror polished stainless steel sheets in commercial building lobbies and entrances can add a luxurious feel and visual impact to the space.

Interior Decoration

Ceilings and Walls: Mirror polished stainless steel sheets are used for interior ceilings and wall decorations, effectively enhancing the brightness and visual appeal of the space, creating a modern and high-end atmosphere.

Elevator Decorations: Mirror polished stainless steel sheets are used in elevator interiors for their aesthetic appeal, durability, and ease of cleaning and maintenance.

Furniture Manufacturing

Tabletops and Cabinet Doors: Applying mirror polished stainless steel sheets to tabletops and cabinet doors increases the texture and style of the furniture, while providing advantages such as wear resistance and easy cleaning.

Furniture Accessories: Using mirror polished stainless steel sheets for handles, decorative strips, and other furniture accessories adds highlights and detailed beauty to the furniture.

Ⅳ. Why you choose Foshan Ferosteel?

Wide Range of Products: We offer a comprehensive range of stainless steel products, including sheets, coils, tubes, and various surface treatment options, to meet the needs of different industries and projects.

High-Quality Products: All our products are made from high-quality stainless steel materials, undergo strict quality control and inspection processes to ensure stable and reliable performance.

Customization Services: We provide customized processing services to tailor stainless steel products in different specifications and surface treatments according to customer requirements, helping customers achieve personalized designs.

Professional Team: We have an experienced professional team that provides technical support and consulting services to ensure we provide the best solutions for you.

Quick Response and Delivery: We promise to respond quickly to customer needs and provide timely delivery services to ensure projects are completed on time.

Ⅴ. FAQ

1.What are the surface treatment methods for mirror polished stainless steel?

Main methods include mirror polishing, brushing, etching, titanium plating, and sandblasting, each providing different visual effects and textures.

2.How do you clean and maintain mirror polished stainless steel?

Use neutral detergent and a soft cloth for daily cleaning. Avoid using cleaners containing chlorine ions to prevent surface corrosion. Regular cleaning helps maintain its brightness and appearance.

3.What are the differences between mirror polished stainless steel and ordinary stainless steel sheets?

Mirror polished stainless steel sheets have undergone multiple polishing and buffing steps to achieve a mirror-like surface, whereas ordinary stainless steel sheets typically have a rougher surface with lower gloss.

4.What are the common specifications of mirror polished stainless steel?

Standard specifications typically include thickness ranging from 0.3mm to 3.0mm, and common widths of 1000mm, 1219mm, 1500mm, etc., with customization available based on customer requirements.

5.What factors affect the price of mirror polished stainless steel?

Price factors include material costs, processing complexity, surface treatment methods, order quantity, etc. Specific pricing is typically provided based on specific requirements.