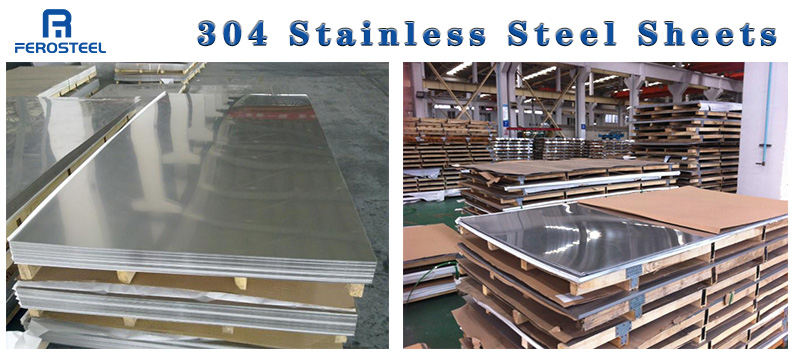

Stainless steel is a versatile and durable material that is widely used in various industries and applications. Among the different types of stainless steel, 304 stainless steel is one of the most popular choices due to its excellent corrosion resistance, high-temperature strength, and aesthetic appeal. In this comprehensive guide, we will explore everything you need to know about 304 stainless steel sheets, including pricing, cutting techniques, and maintenance tips.

Pricing of 304 Stainless Steel Sheets

When it comes to purchasing 304 stainless steel sheets, the pricing can vary depending on several factors. The thickness, size, and finish of the sheet will all impact the cost. Additionally, market conditions and the supplier’s pricing strategy will also play a role in determining the final price. On average, the price of a standard 304 stainless steel sheet can range from $100 to $300 per sheet, but this can fluctuate based on the aforementioned factors.

To get an accurate price for a sheet of 304 stainless steel, it’s essential to reach out to multiple suppliers and compare quotes. Keep in mind that while price is important, the quality and reputation of the supplier should also be taken into consideration. Look for suppliers who offer competitive pricing without compromising on the quality of the material.

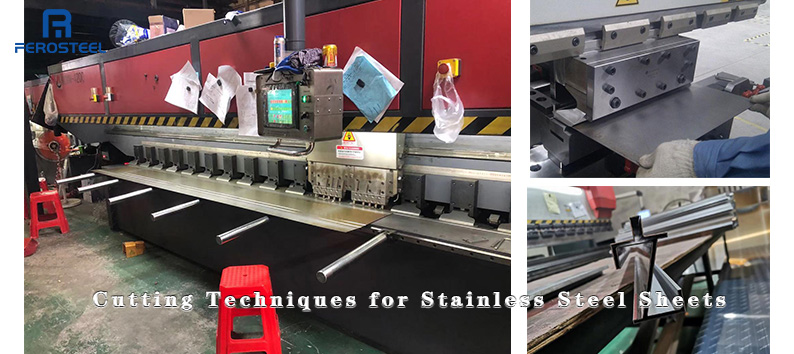

Cutting Techniques for Stainless Steel Sheets

Cutting stainless steel sheets can be a challenging task, especially if you don’t have the right tools and techniques. Whether you’re a DIY enthusiast or a professional fabricator, it’s crucial to use the appropriate cutting method to achieve clean and precise results. Here are some common techniques for cutting stainless steel sheets:

- Shearing: This method involves using a shear or guillotine to cut through the stainless steel sheet. Shearing is ideal for straight cuts and is suitable for sheets with a thickness of up to 6mm.

- Plasma Cutting: Plasma cutting is a versatile and efficient method for cutting stainless steel sheets. It uses a high-velocity jet of ionized gas to melt and remove the metal, resulting in a smooth and accurate cut.

- Laser Cutting: Laser cutting is a precise and high-speed cutting method that is well-suited for intricate designs and patterns. It utilizes a focused laser beam to vaporize the material along the desired cutting path.

- Waterjet Cutting: Waterjet cutting is a cold cutting process that uses a high-pressure stream of water mixed with an abrasive substance to cut through the stainless steel sheet. This method is suitable for a wide range of thicknesses and does not produce heat-affected zones.

Before proceeding with any cutting technique, it’s essential to take proper safety precautions and use the necessary protective equipment. Additionally, consider the specific requirements of your project to determine the most suitable cutting method for your 304 stainless steel sheet.

Maintenance Tips for 304 Stainless Steel Sheets

Proper maintenance is crucial for preserving the appearance and performance of 304 stainless steel sheets. Whether used in architectural applications, kitchen equipment, or industrial machinery, stainless steel requires regular care to prevent corrosion and maintain its luster. Here are some essential maintenance tips for 304 stainless steel sheets:

- Regular Cleaning: To keep stainless steel sheets looking their best, regular cleaning is essential. Use a mild detergent or stainless steel cleaner and a soft cloth to remove dirt, fingerprints, and smudges. Avoid using abrasive cleaners or scouring pads, as they can scratch the surface of the stainless steel.

- Passivation: Passivation is a chemical treatment that helps remove free iron and other contaminants from the surface of stainless steel, thereby enhancing its corrosion resistance. This process is particularly important for 304 stainless steel sheets that are exposed to harsh environments or corrosive substances.

- Avoid Contamination: Stainless steel is susceptible to contamination from carbon steel, iron particles, and other metal debris. To prevent contamination, use separate tools and equipment when working with stainless steel sheets, and avoid contact with materials that can cause galvanic corrosion.

- Protective Coatings: In some applications, applying a protective coating or film to the surface of the stainless steel sheet can provide an extra layer of protection against scratches, stains, and corrosion. Be sure to select a coating that is compatible with stainless steel and follow the manufacturer’s guidelines for application.

By following these maintenance tips, you can prolong the lifespan of your 304 stainless steel sheets and ensure that they continue to meet your performance requirements.

In conclusion, 304 stainless steel sheets are a valuable material with a wide range of applications, from construction and manufacturing to household and decorative uses. Understanding the pricing factors, cutting techniques, and maintenance tips for 304 stainless steel sheets is essential for making informed decisions and maximizing the benefits of this versatile material. Whether you’re purchasing stainless steel sheets for a specific project or looking to enhance the performance of existing installations, the knowledge and insights shared in this guide will serve as a valuable resource.