Stainless steel sheets are an essential material in various industries due to their durability, versatility, and aesthetic appeal. Whether you’re considering brushed stainless steel or mirror polished stainless steel sheets, understanding their features and applications is crucial for making informed decisions.

In this comprehensive guide, we’ll delve into the world of stainless steel sheets, exploring the differences between brushed and regular stainless steel, as well as the properties and benefits of mirror polished finishes. Additionally, we’ll provide valuable insights on choosing the right stainless steel sheet, installation tips, and maintenance guidelines. By the end of this article, you’ll have a solid understanding of stainless steel sheets and be equipped with the knowledge needed to embark on your next project with confidence.

Understanding Brushed Stainless Steel vs. Stainless Steel

Key Differences between Brushed and Regular Stainless Steel

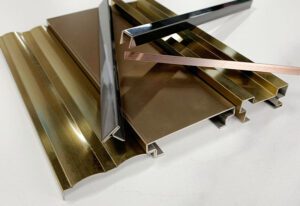

Visual Appearance: Brushed stainless steel has a distinctive linear texture, while regular stainless steel has a smooth, polished surface.

Reflectivity: Brushed stainless steel has a lower reflectivity compared to regular stainless steel, which can have a mirror-like shine.

Hiding Fingerprints and Scratches: The brushed texture of stainless steel sheets helps to camouflage fingerprints and minor scratches, making them less visible compared to regular stainless steel.

Aesthetic Appeal: Brushed stainless steel offers a modern, industrial look that is often favored for contemporary designs, while regular stainless steel can provide a more classic, polished appearance.

Applications and Common Uses for Brushed Stainless Steel Sheets

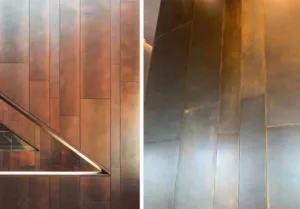

Interior Design: Brushed stainless steel sheets are commonly used in kitchens, bathrooms, and commercial spaces for countertops, backsplashes, and wall cladding.

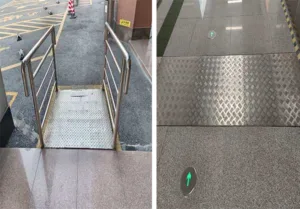

Architectural Applications: They are utilized for building facades, elevator panels, handrails, and decorative elements.

Furniture and Appliances: Brushed stainless steel sheets are employed in the manufacturing of furniture, appliances, and fixtures, such as tables, chairs, refrigerators, and sinks.

Automotive Industry: They can be found in car interiors, trim, and accents due to their durability and aesthetic appeal.

By understanding the differences between brushed stainless steel and regular stainless steel, you can make informed decisions when selecting the appropriate finish for your specific applications and design preferences.

Exploring Mirror Polished Stainless Steel Sheets

Definition and Features of Mirror Polished Stainless Steel

- Mirror polished stainless steel is a highly reflective finish achieved through a polishing process that creates a mirror-like surface.

- The polishing process involves progressively finer abrasives to remove any imperfections and achieve a smooth, reflective surface.

- Mirror polished stainless steel sheets exhibit a high level of reflectivity and a bright, lustrous appearance.

Comparing Mirror Polished and Brushed Stainless Steel Sheets

- Appearance: Mirror polished stainless steel has a highly reflective, mirror-like appearance, while brushed stainless steel has a textured, matte finish.

- Reflectivity: Mirror polished stainless steel has a significantly higher reflectivity than brushed stainless steel.

- Visibility of Imperfections: Scratches and fingerprints are more visible on mirror polished surfaces compared to brushed finishes.

- Design Compatibility: Mirror polished stainless steel is often associated with contemporary and high-end designs, while brushed stainless steel complements a variety of styles, including industrial and modern aesthetics.

Choosing the Right Stainless Steel Sheet

Factors to Consider When Selecting Stainless Steel Sheets

- Purpose and Application: Consider the specific purpose and intended use of the stainless steel sheet, such as whether it will be exposed to corrosive environments, high temperatures, or aesthetic requirements.

- Size and Thickness: Determine the appropriate size and thickness of the sheet based on the project requirements and structural considerations.

- Strength and Durability: Evaluate the strength and durability needed for the application, considering factors such as load-bearing capacity and resistance to impact or deformation.

- Corrosion Resistance: Assess the level of corrosion resistance required, considering the environment, exposure to chemicals, and moisture.

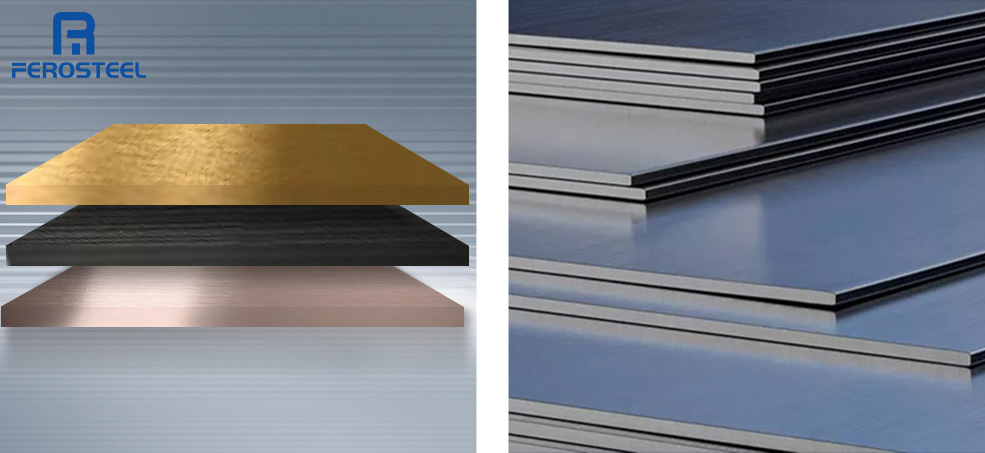

- Aesthetic Considerations: Take into account the desired appearance, texture, and finish of the stainless steel sheet to ensure it aligns with the overall design vision.

Determining the Appropriate Finish for Your Project

- Assess the desired aesthetic outcome and functional requirements of the project to determine the appropriate finish for the stainless steel sheet.

- Consider finishes such as brushed, mirror polished, satin, or embossed, based on factors like visual appeal, durability, ease of maintenance, and compatibility with the overall design concept.

- Take into account factors such as fingerprint resistance, scratch hiding ability, and reflectivity when deciding on the finish.

Factors Impacting Cost and Maintenance

- Understand that different grades, finishes, and sizes of stainless steel sheets can vary in cost.

- Consider the budget constraints and balance them with the desired properties and aesthetics.

- Take into account the long-term maintenance requirements of the chosen stainless steel sheet, including cleaning procedures, frequency of maintenance, and potential costs associated with upkeep.

Installation and Maintenance Tips for Stainless Steel Sheets

A. Proper Handling and Installation Techniques

- Carefully handle stainless steel sheets to avoid scratching or damaging the surface. Use gloves and protective covers when necessary.

- Ensure a clean and dry installation area to prevent contamination or moisture buildup.

- Follow manufacturer guidelines for installation methods, including appropriate fasteners, adhesives, or mounting systems.

- Use tools specifically designed for stainless steel to avoid potential damage.

B. Cleaning and Maintenance Guidelines for Different Finishes

- Brushed Stainless Steel:

- Regularly clean brushed stainless steel sheets using mild soap or a stainless steel cleaner and a soft cloth or sponge.

- Wipe in the direction of the grain to maintain the brushed finish and minimize the visibility of scratches.

- Avoid using abrasive cleaners, scouring pads, or steel wool, as they can damage the surface.

- Rinse thoroughly and dry the surface after cleaning to prevent water spots.

- Mirror Polished Stainless Steel:

- Clean mirror polished stainless steel sheets with a non-abrasive, stainless steel-specific cleaner and a soft, lint-free cloth.

- Gently wipe the surface in a circular motion to remove fingerprints, smudges, and other residues.

- Avoid using rough or abrasive materials that can scratch or dull the mirror finish.

- Polish the surface occasionally with a specialized stainless steel polish to maintain its shine.

C. Preventing and Treating Stains or Corrosion

- Regularly inspect stainless steel sheets for signs of stains, corrosion, or pitting.

- Immediately clean up spills or stains to prevent potential damage. Use mild cleaners or stainless steel-specific stain removers as recommended.

- Avoid prolonged exposure to corrosive substances such as acids, salts, or chlorides.

- Apply a protective coating or clear lacquer if the stainless steel sheets will be exposed to harsh environments or high levels of moisture.

- Consult with professionals if stains or corrosion occur beyond regular maintenance, as they may require specialized treatments or repairs.

Frequently Asked Questions (FAQs)

What is the Difference Between Stainless Steel and Other Metals?

Stainless steel is an alloy primarily composed of iron, chromium, and other elements, which provides it with unique properties such as corrosion resistance, durability, and strength.

Unlike other metals, stainless steel has a protective layer of chromium oxide that forms on its surface, making it highly resistant to rust and corrosion.

How to Identify High-Quality Stainless Steel Decorative Sheets?

Look for reputable suppliers and manufacturers who provide certifications and documentation confirming the quality and composition of the stainless steel sheets.

Check for proper labeling and markings on the sheets, including grade, alloy, and relevant standards.

High-quality stainless steel sheets should have a consistent finish, with no visible defects, scratches, or dents.

Consider seeking recommendations from experts or professionals in the industry to ensure you are purchasing reliable and high-quality stainless steel sheets.

Can Stainless Steel Decorative Sheets Be Customized?

Yes, stainless steel sheets can be customized to suit specific project requirements.

Customization options include selecting the desired size, thickness, grade, finish, and shape of the sheets.

Consult with manufacturers or suppliers who offer customization services to discuss your specific needs and determine the feasibility of customization.