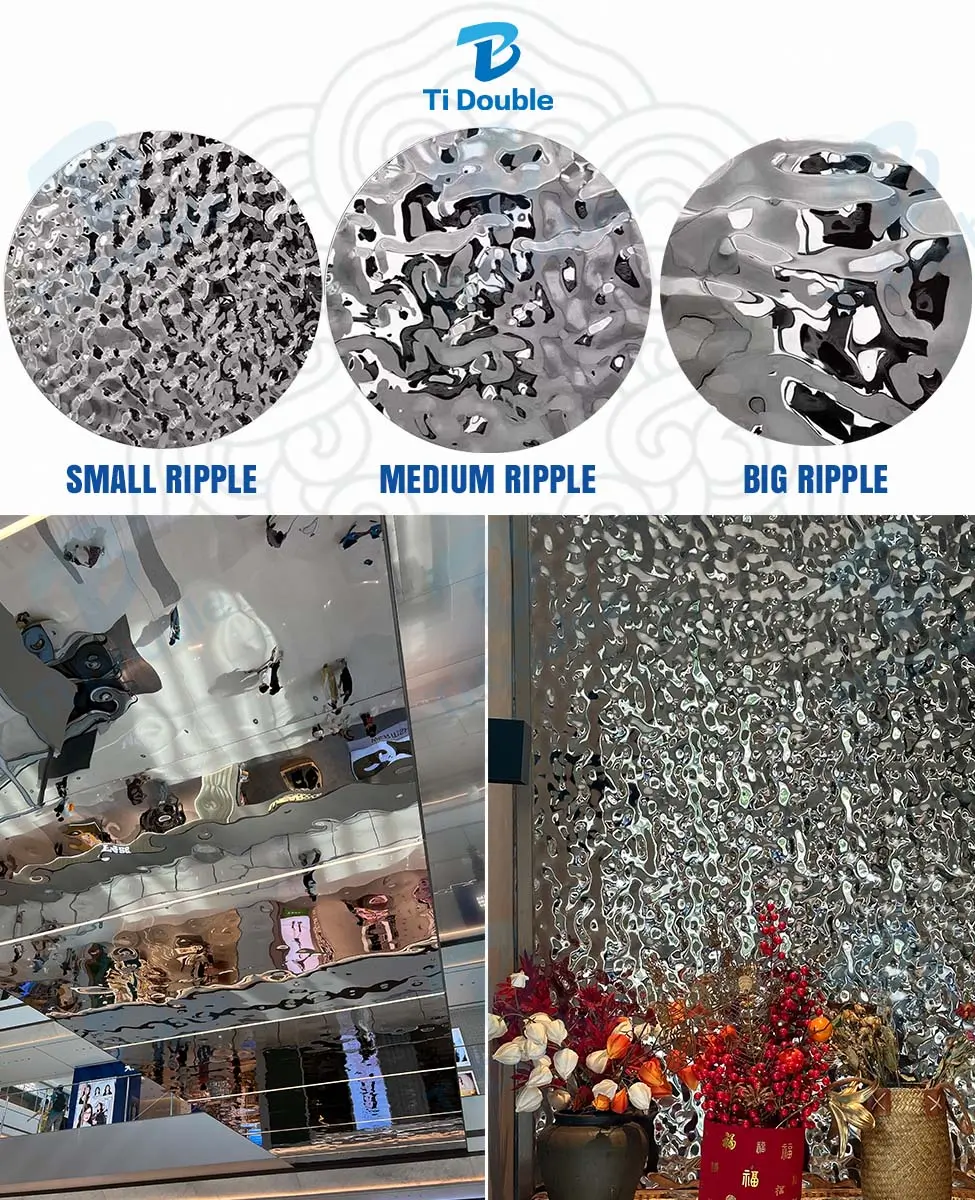

WATER RIPPLE STAINLESS STEEL SHEET

Water Ripple Sheets

Our high-quality and unique design will add a touch of elegance and sophistication to any space. Whether you are looking to enhance your home, office, or commercial space, our water ripple stainless steel sheets are the perfect choice.

Benefits of Water Ripple Stainless Steel Sheets:

Decorative New Metal Materials

Water Ripple Stainless Steel Sheet Manufacturer

Genuine Stainless Steel

The detail

No Glue Dropping

The detail

Diverse Customization Options

The detail

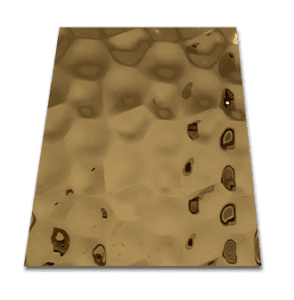

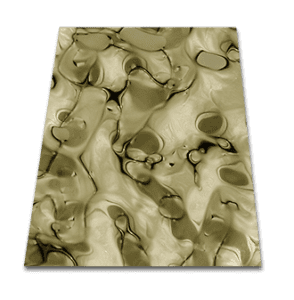

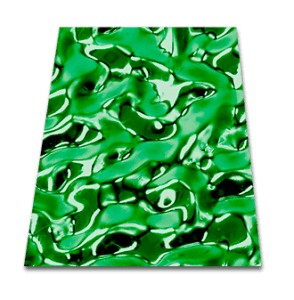

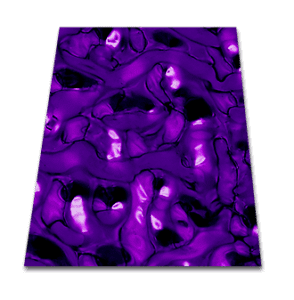

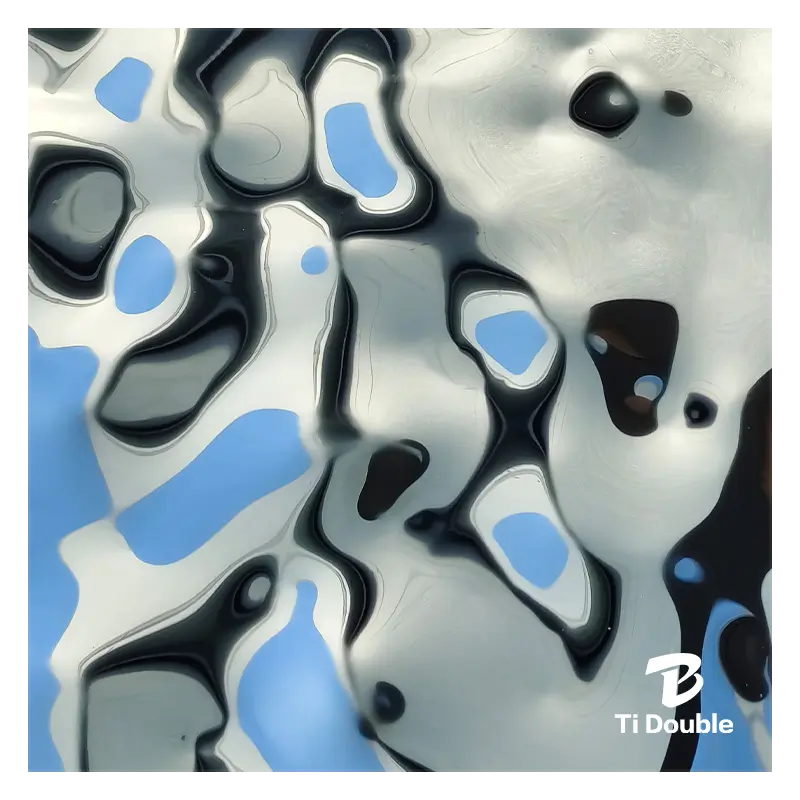

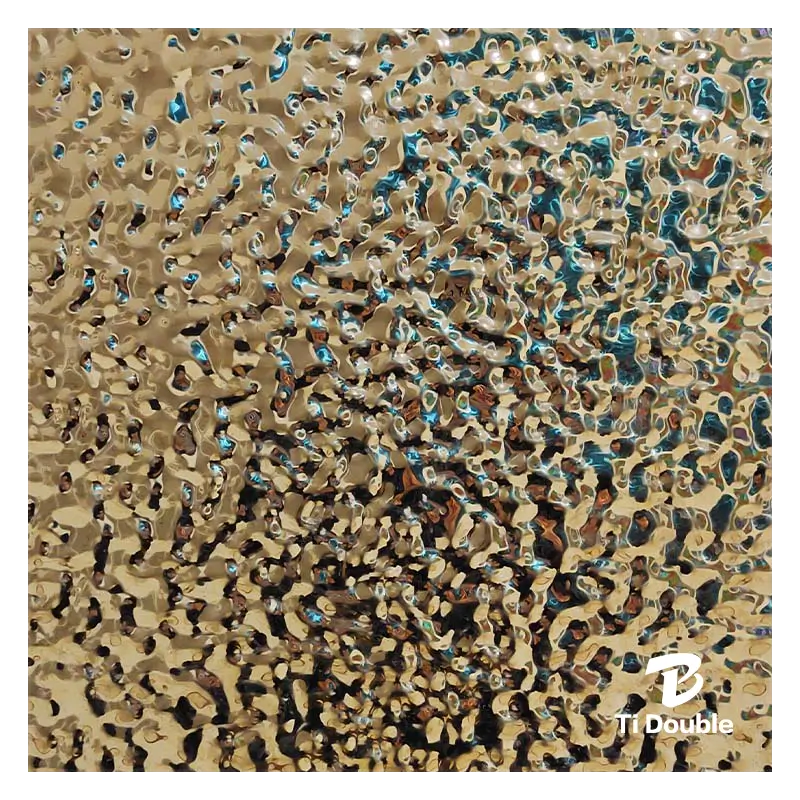

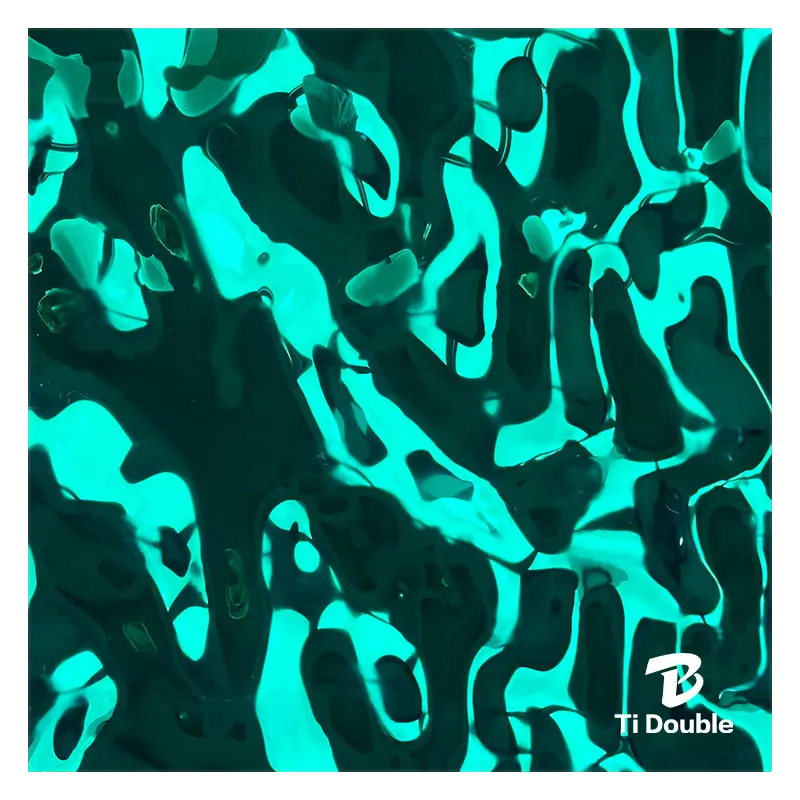

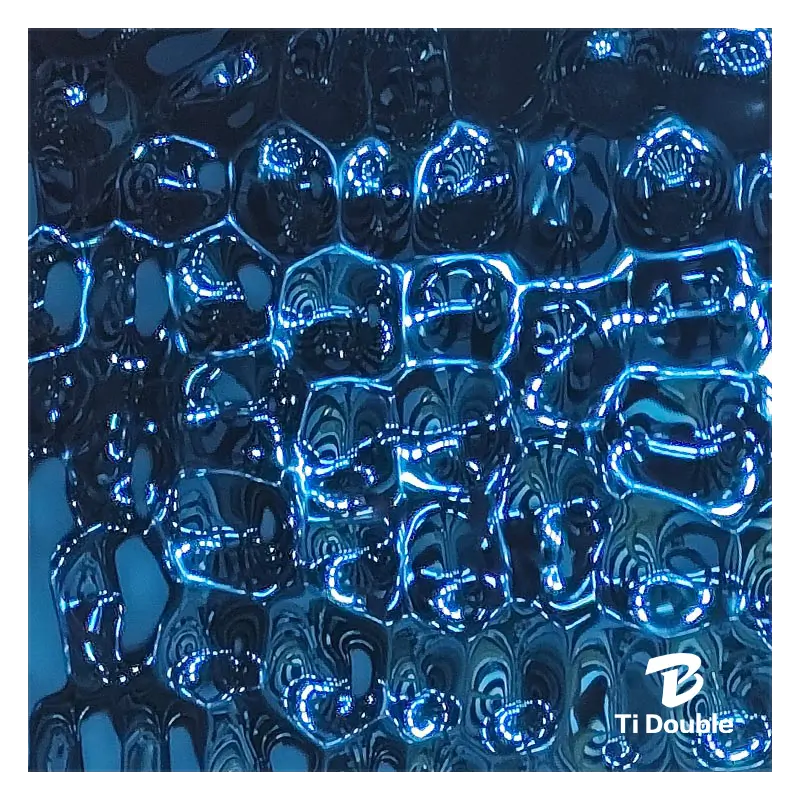

Multiple Color Surface

Up to 18+ colors available for choosing! our water ripple sheet metal can make gold, rose gold and other colors in different surface.

| Products Name | Water Ripple Stainless Steel Sheets |

| Material | SUS304 SUS316L ETC.. |

| Color | Silver, Gold, Rose Gold, Champagne, Copper, Bronze, Black & Blue |

| Length | max 5500mm |

| Width | 1000mm, 1220mm, 1250mm,1500MM |

| Thickness | 0.6-2.0mm |

| Tolerance | +/- 5% |

| APPLICATION | Interior & exterior wall cladding, facade, ceiling, luxurious interior design and more |

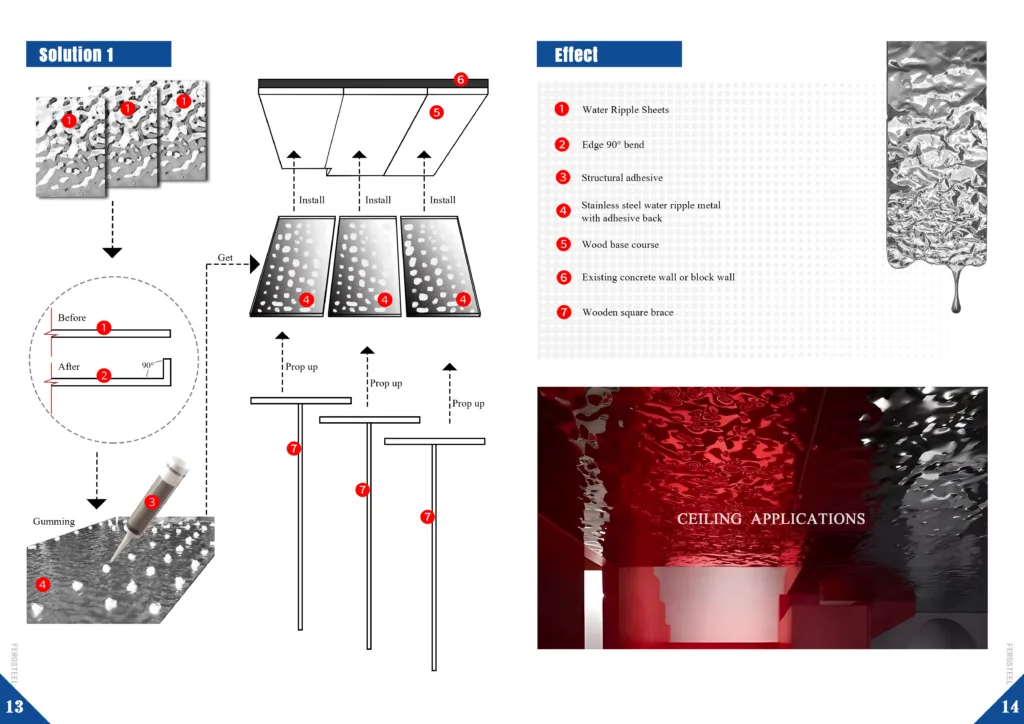

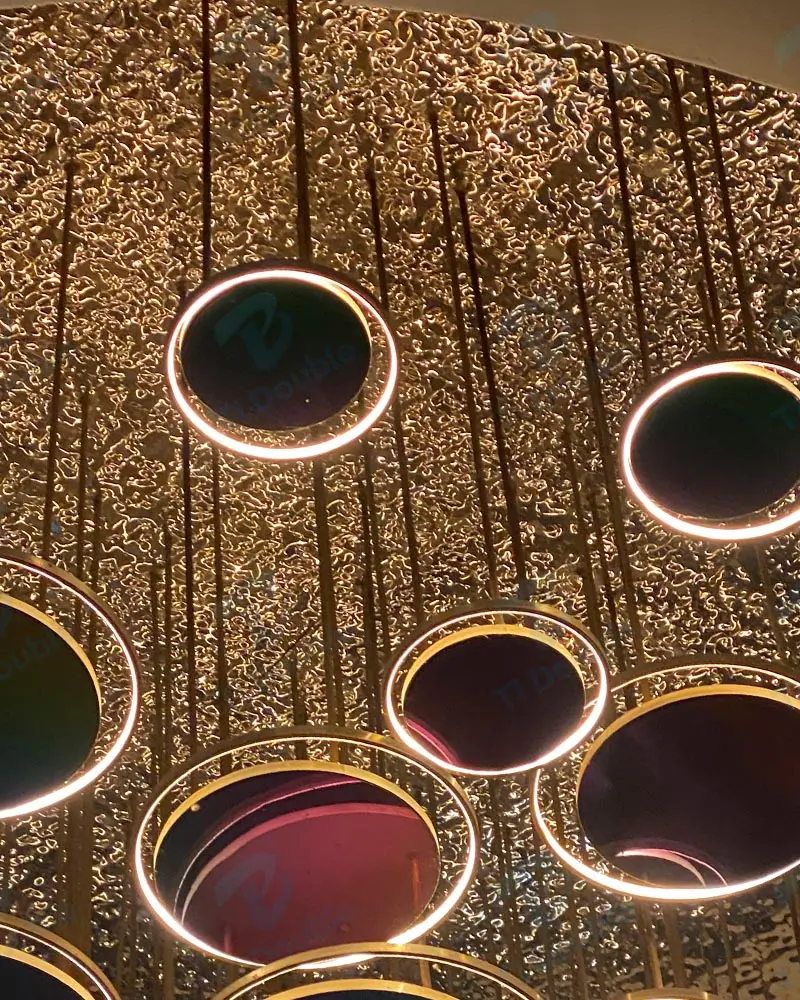

Water Ripple Stainless Steel Sheets Wall Installation

Structural Adhesive Method | Four-Step Guide

Water ripple stainless steel sheets are widely used in commercial and high-end interior wall applications for their unique three-dimensional texture and decorative appeal. Among various installation methods, structural adhesive fixing is an efficient and widely used solution that ensures a clean surface finish without drilling damage. Proper installation guarantees excellent flatness, strong bonding, and long-term stability.

Below is the standard four-step installation method using structural adhesive:

Step 1: Wall Surface Preparation

Ensure the wall surface is solid, flat, dry, and free from dust, oil, or loose materials. If the wall surface is uneven, it should be leveled in advance to guarantee a smooth and uniform installation result.

Step 2: Sheet Cleaning & Positioning

Before installation, clean the back of the water ripple stainless steel sheets using alcohol or a neutral cleaning agent to remove any oil or impurities. Mark reference lines according to the design layout and confirm the correct installation direction and consistency of the ripple pattern.

Step 3: Structural Adhesive Application & Installation

Apply structural adhesive evenly on the back of the sheet using dot or strip application methods, ensuring proper spacing to avoid hollow areas. Align the sheet with the reference lines, place it onto the wall, and press gently to ensure even bonding.

Step 4: Alignment, Fixing & Curing

After installation, adjust the sheet alignment and joint gaps promptly. Temporary supports may be used if necessary. Once the structural adhesive has fully cured (typically 24–48 hours), remove the protective film and complete the edge finishing.

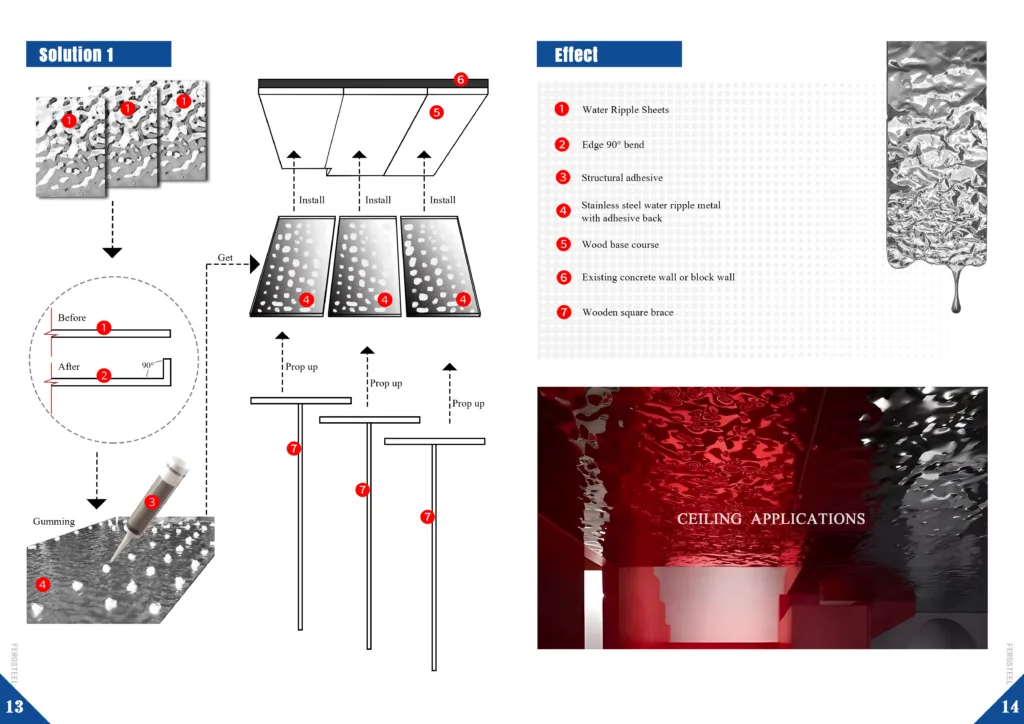

Structural Adhesive Method | Suspended Ceiling Guide

Water ripple stainless steel sheets are widely applied in commercial spaces, hotel lobbies, shopping malls, and luxury interior ceilings due to their distinctive ripple texture and modern decorative effect. For ceiling applications, structural adhesive fixing is an effective installation method that allows for a clean, seamless appearance while avoiding visible fasteners. When combined with proper structural support, this method ensures reliable bonding, long-term stability, and a refined ceiling finish.

Below is the standard installation procedure for water ripple stainless steel ceiling :

Step 1: Ceiling Framework & Base Preparation

Ensure the ceiling base structure or metal framework is stable, level, and securely fixed. The surface should be clean, dry, and free from dust, oil, or loose materials. If necessary, install a suitable backing board (such as cement board or metal panel) to provide a solid bonding surface.

Step 2: Sheets Cleaning & Layout Marking

Clean the back of the water ripple stainless steel panels with alcohol or a neutral cleaning agent to remove any contaminants. Mark reference lines on the ceiling according to the design layout, ensuring correct alignment and consistent ripple direction across all sheets.

Step 3: Structural Adhesive Application & Installation

Apply structural adhesive evenly on the back of the panels using dot or strip patterns, with appropriate spacing to ensure full adhesion and prevent hollow areas. Carefully lift and position the panel onto the ceiling base, pressing gently to achieve even contact and proper bonding.

Step 4: Temporary Support & Curing

Use temporary supports or mechanical fixtures to hold the panels in place during curing, especially for overhead installation. Allow the structural adhesive to fully cure (typically 24–48 hours) before removing supports, peeling off the protective film, and completing edge trims or joint finishing.

Water Ripple Stainless Steel Ceiling Installation

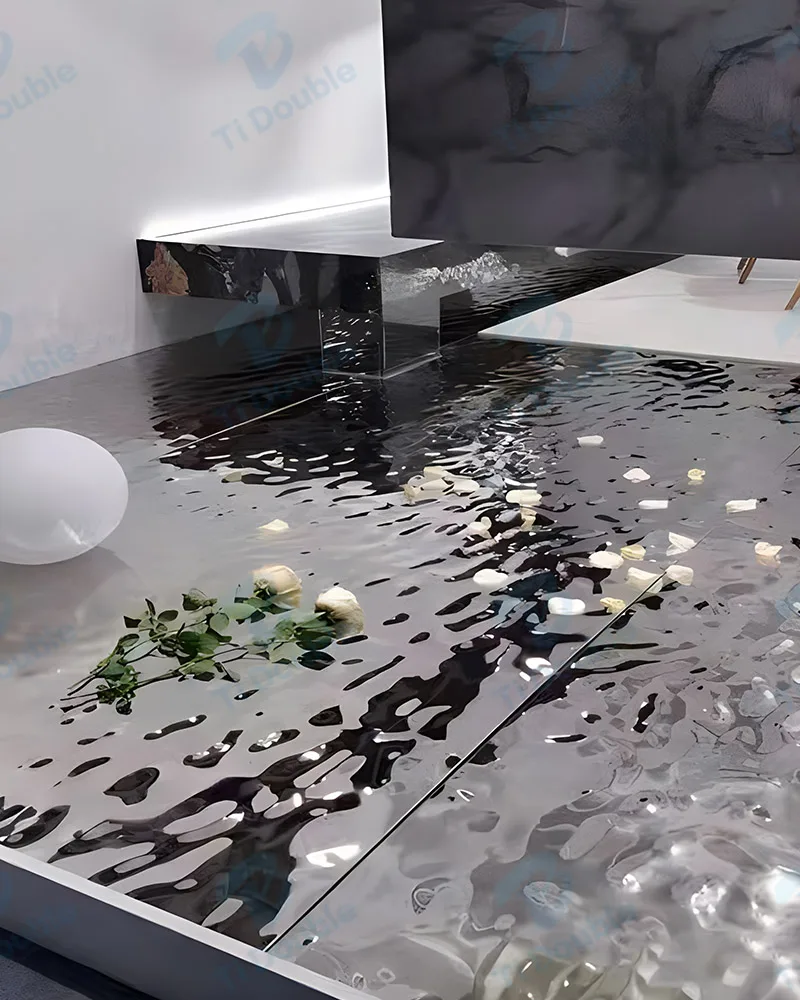

Applications For Water Ripple Stainless Steel

Water ripple stainless steel sheets are widely used as building decorative sheet metal materials for commercial or residential interior and exterior decoration and engineering projects, you can install them to decor your walls, ceilings, bar counters, background walls and even the exterior and doors of elevators.

The water ripple metal material is recognized by the customer

We used these water ripple stainless steel sheets for a hotel ceiling project. The installation was smooth, and the final decorative effect is very premium and modern.

Ahmed Al-Farsi Procurement Manager | Hotel DevelopmentGreat supplier for decorative stainless steel. The water ripple sheets added a unique visual impact to our commercial interior project.

Carlos Martínez Interior Designer | Commercial Space Design StudioThe panels were perfectly packaged, and the surface quality was excellent with no scratches. Our local clients really love the water ripple design.

Sarah Williams Purchasing Manager | Building Materials DistributorWhy Choose Water Ripple Metal Sheets for Your Project

Aesthetic Appeal

The unique water ripple design creates an elegant and visually captivating surface, adding a sophisticated touch to any setting.

Distinctive Texture

The textured surface provides a tactile experience, enhancing both the visual and sensory appeal of any environment.

Corrosion Resistance

Offering excellent resistance to corrosion, water ripple stainless steel is durable and ideal for various applications.

Durability

The robust nature of stainless steel ensures that the water ripple finish can withstand heavy use while maintaining its appearance.

Reflective Quality

The rippled surface interacts beautifully with light, creating dynamic reflections and adding depth to spaces.

Modern Appeal

The contemporary look of water ripple stainless steel aligns perfectly with modern and minimalist design trends, making it a popular choice for designers and architects.

Benefits Of Water Ripple Stainless Steel Sheet Metal

- Unique Visual Appeal: The water ripple pattern on the stainless steel sheet creates a visually striking and unique appearance. It adds depth, texture, and a sense of movement to the surface, making it an eye-catching feature in various applications.

- Reflective Properties: Stainless steel has inherent reflective properties, and the water ripple pattern further enhances this characteristic. The ripples create a play of light and shadow, resulting in an attractive visual effect that can add a touch of elegance and sophistication to any space.

- Durability: Stainless steel is renowned for its exceptional durability. It is resistant to corrosion, tarnishing, and rust, making it suitable for both indoor and outdoor applications. The water ripple pattern does not compromise the inherent strength and longevity of stainless steel, ensuring that the sheet metal remains robust and long-lasting.

- Versatility: Water ripple stainless steel sheet metal is highly versatile in terms of application. It can be used in architectural designs, interior decor, furniture, signage, wall cladding, and more. The unique pattern can be customized to fit specific design requirements, offering flexibility to designers and architects.

- Easy Maintenance: Stainless steel is known for its low maintenance requirements. It is easy to clean, and the water ripple pattern does not impede the cleaning process. Regular wiping with a mild detergent and a soft cloth is usually sufficient to maintain its appearance and shine.

- Hygienic Properties: Stainless steel is inherently hygienic, making it an ideal choice for applications where cleanliness is essential. It is non-porous, resistant to bacterial growth, and easy to sanitize, making it suitable for use in kitchens, healthcare facilities, and other environments where hygiene is a priority.

- Sustainability: Stainless steel is a sustainable material choice. It is 100% recyclable, which means it can be repurposed and reused at the end of its lifecycle. Additionally, stainless steel is made from a high percentage of recycled content, reducing the demand for raw materials and minimizing environmental impact.

By Sea Packaging

Airway Packaging

Water Ripple Sheets FAQs

Water ripple stainless steel sheets is a unique decorative material, we often use it for ceilings, wall decorations, etc.

When our customers ask how to install it, we have also compiled a water ripple stainless steel ceiling installation video and water ripple installation plan for our customers.

Foshan ferosteel Co., Ltd. is a stainless steel decorative plate supplier, focusing on 14 years of experience in the stainless steel industry. We can provide a variety of stainless steel decorative plates such as water ripple stainless steel sheets, support customization and free sample service.

Related product recommendation

In addition to water ripple stainless steel sheets, there are various other types of decorative stainless steel sheets. All of these can bring you added value, such as aesthetics, corrosion resistance, durability, etc. But different finish options offer different characteristics, performance, and processing costs, so it’s critical to consider your specific needs when choosing the right finish for your stainless steel plate.

The water ripple stainless steel sheets have an excellent surface finish and very consistent ripple texture. The quality exceeded our expectations, and the panels look outstanding on the wall.

Michael Anderson Project Manager | Commercial Interior Projects