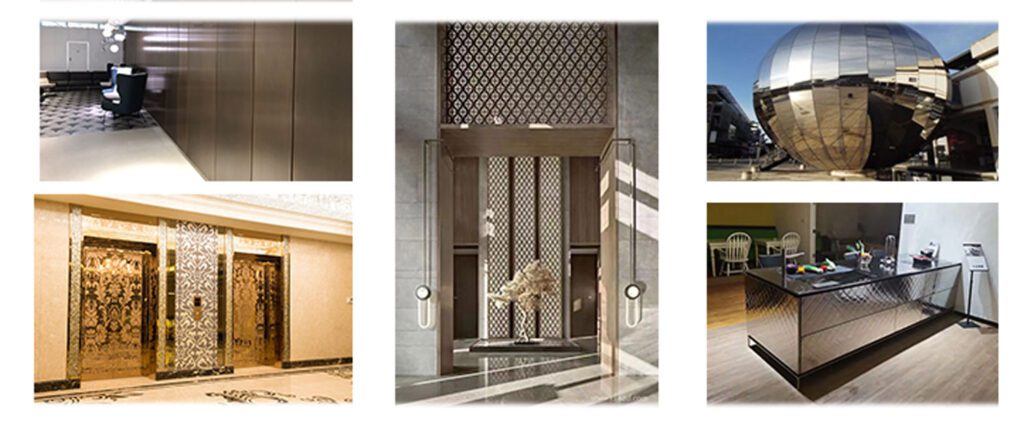

As a leading brand in the processing of stainless steel decorative Sheets, our brand, Ferosteel, with its 14 years of professional experience, is committed to providing customers with diversified solutions for stainless steel surface treatments. From etching, brushing, and mirror finishes to plating, stamping, and embossing, our professional team can meet various design requirements, giving your products personalized appearances and superior performance attributes.

Stainless steel is a premium material known for its excellent corrosion resistance and aesthetic appeal, making it suitable for various applications. To meet diverse design requirements, ss surfaces can undergo various processing techniques, imparting different appearances and performance attributes. Here are several common surface treatment techniques for stainless steel:

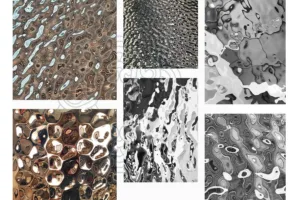

Etching finish:

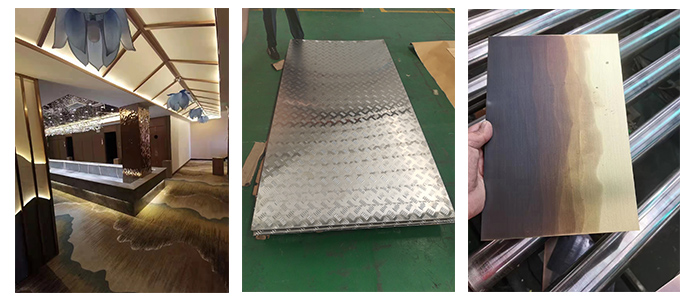

Etching is a process that utilizes chemical corrosion to create patterns or textures on ss surfaces. By applying acid-resistant material on the surface and selectively etching desired areas, intricate patterns and designs can be achieved. Etching enhances the decorative aspect of stainless steel and finds applications in artworks, decorative panels, etc.

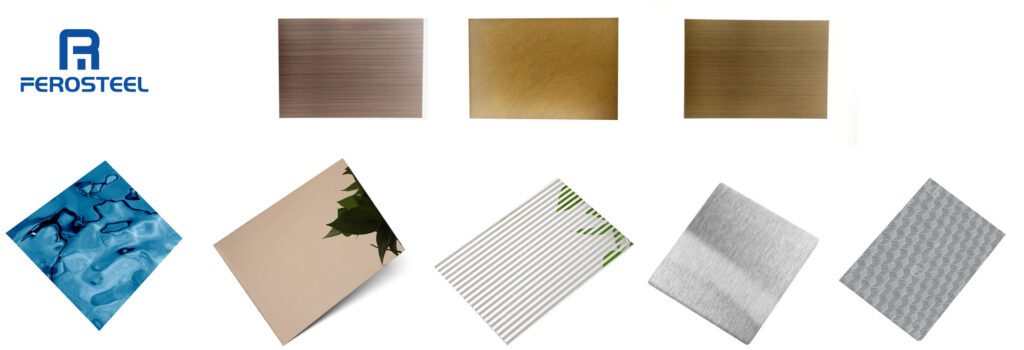

Brushing finsih:

Brushing involves creating linear textures on surfaces through mechanical means. Typically, abrasive wheels or brushes are used to brush the surface, resulting in directional texture effects. Brushing enhances the tactile quality and surface hardness of stainless steel, commonly used in furniture, kitchenware, and other products.

Mirror Finish:

Mirror finish treatment involves polishing ss surfaces to a highly smooth and reflective state using mechanical or chemical methods. This process imparts a mirror-like appearance with exceptional brightness and reflectivity. Mirror finish finds applications in high-end decorative items, architectural facades, etc.

PVD Plating:

Plating is a process of depositing a layer of metal or alloy onto stainless steel surfaces to alter their appearance and provide additional functionalities. Common plating options include chrome plating, nickel plating, copper plating, etc., offering various colors and textures. Plating treatment is used in decorative items, hardware accessories, etc.

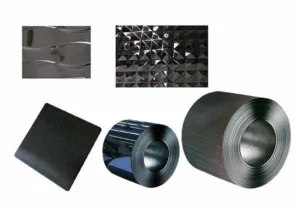

Stamping Finsih:

Stamping involves shaping ss sheets into desired forms using molds. Through stamping, various indentations, patterns, and structures can be created on stainless steel surfaces, allowing for customized shapes and decorative effects. Stamping is commonly applied in automotive parts, household appliance casings, etc.

Embossing Finish:

Embossing is a process of applying pressure to stainless steel surfaces to create raised patterns or textures. Popular embossing methods include roll embossing, indentation embossing, etc., yielding different decorative effects and tactile sensations. Embossing treatment is prevalent in decorative panels, door and window fittings, etc.

These surface treatment techniques offer ss sheets a wide range of design possibilities to meet diverse aesthetic and performance requirements. When selecting suitable treatment techniques, factors such as product design, usage environment, and cost should be considered to achieve the best results.

Through Ferosteel skilled craftsmanship, the diversified surface treatment of stainless steel has become the preferred choice for designers and manufacturers. We firmly believe that with continuous technological innovation and the ongoing efforts of our brand, stainless steel will demonstrate its diversity and superiority in more fields, creating even more refined and practical decoration and lifestyle experiences for you. We look forward to partnering with you to create a better future together!

Stainless Steel FAQs

What are the benefits of stainless steel surface treatment?

Stainless steel surface treatment offers several benefits including enhanced aesthetic appeal, improved corrosion resistance, increased durability, and customization options to meet specific design requirements.

How do I choose the right surface treatment for my stainless steel product?

The choice of surface treatment depends on factors such as the intended use of the product, desired appearance, environmental conditions, and budget. Consulting with a professional or supplier can help determine the most suitable treatment for your needs.

Is stainless steel surface treatment environmentally friendly?

Many Finish treatment processes can be environmentally friendly, especially those that utilize mechanical methods or eco-friendly chemicals. However, it’s essential to consider the environmental impact of each treatment method and opt for processes with minimal environmental footprint whenever possible.