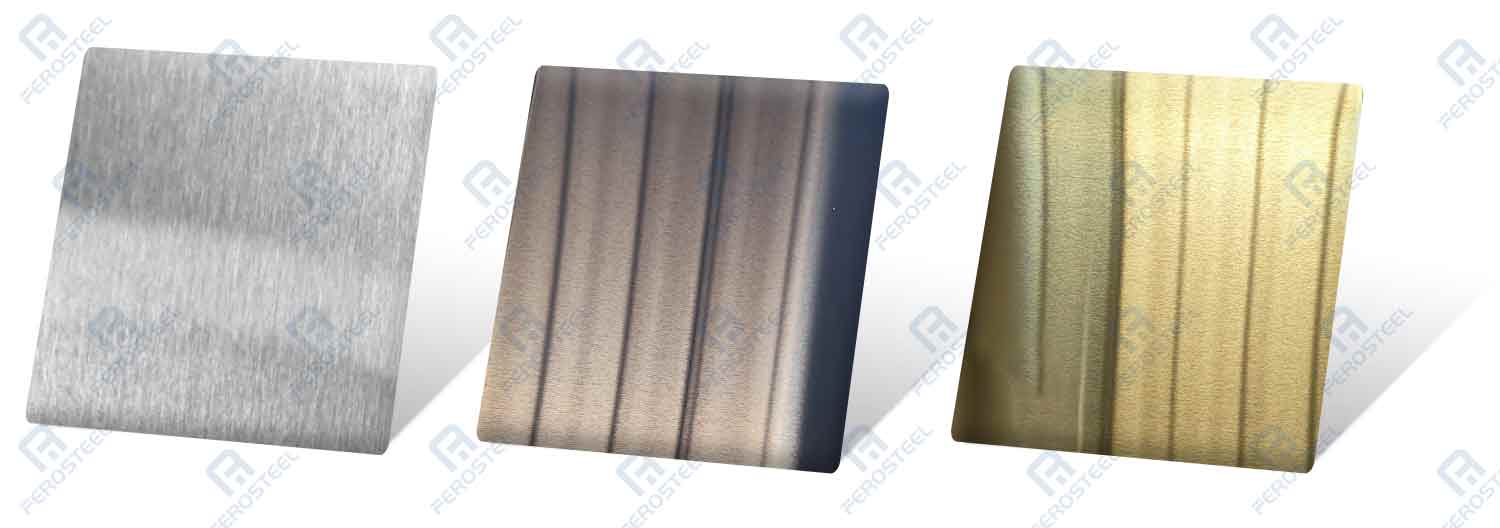

The surfaces we often see in the field of metal decorative materials – brushed series usually include: NO.4 surface, satin surface, hairline finish.

Although they are in the same category, each surface treatment has unique characteristics that make them unique.

Before delving into their differences, let’s first understand the general process and overview of No.4 finishes.

No.4 Finish

304 #4 stainless steel plate is an excellent candidate for most processing technologies as well as indoor and outdoor applications. 304 #4 stainless steel is a high-strength material with excellent corrosion resistance, so it is also commonly used in aerospace structures, pressure vessels, architectural design, food and beverage industry equipment, and more.

It is worth noting that the No4 finish has a lower processing cost, making it a cost-effective choice for many applications. While the unit cost of coils is generally lower, the choice between coils and sheet forms depends on the desired quantity of the finished product.

Satin finish

In metal polishing, satin finish is any surface that gives a surface a more grain-like, brushed, or grooved appearance. While satin finishes still reflect light and produce a sparkling effect, they do not achieve the high gloss of a mirror finish. Satin finishes may be ideal for a variety of reasons, including lower maintenance requirements. Additionally, a dull, dull appearance may be better suited to areas with a lot of light to reduce glare.

hairline finish

In the field of metal decoration, hairline stainless steel decorative sheets are also commonly used, and are widely used in elevator decoration, hotel decoration, and other fields.

A hairline finsih, as the name suggests, is a finishing that mimics the appearance of human hair. It is achieved by polishing the metal with 150-180 grains of abrasive tape or grinding wheel and then softening it with 80-120 grains of fat-free compound or medium non-woven fabric abrasive tape or pad. Such results are achieved in finishing long continuous lines with a subtle gloss. A hairline finish is commonly used for architectural applications, kitchen appliances, and automotive detailing. The processing cost of a hairline finish stainless steel is usually higher than that of a size 4 finish.

In the brushed surface series, No. 4, stain, hairline finish all have these different styles, but they are all processed in a similar way, forming different surfaces. Whether you are looking for a solution that provides durability, aesthetic appeal, or a combination of the two, the brush surface series has something to offer.

If you have any questions or ideas about stainless steel decorative plates, please contact us in time for more relevant information. Foshan Ferosteel Co., Ltd. has 14 + years of stainless steel experience to provide you with high-quality service and product guarantee.

Brushed Stainless Steel – Frequently Asked Questions

How to clean brushed stainless steel?

Clean the brushed stainless steel with a soft cloth stained with dust, gently wipe it along the lines, and then dry it with a soft cloth. You can choose to use a special stainless steel cleaner or polish, and polish it with a microfiber cloth to achieve a streak-free effect.

Will brushed stainless steel rust?

The material of the brushed finish is stainless steel. Stainless steel is characterized by corrosion resistance and rust resistance, so the probability of rust in brushed stainless steel is very low. Once the protective layer of brushed stainless steel wears, it will rust over time. 201 stainless steel generally has a lifespan of more than 10 years.

What is brushed stainless steel?

Brushed stainless steel surface treatment is a textured surface treatment suitable for stainless steel. It is achieved by brushing metal with abrasive, creating a unique fine parallel line pattern. And No. 4, stain, hairline finish are all product styles in the brushed series.