Discover the beauty and practicality of colored stainless steel sheets with their easy maintenance and cleaning requirements. Colored stainless steel sheets add a vibrant touch to various applications, from architectural designs to automotive accessories.

To keep your colored stainless steel sheets looking their best, simply clean them with mild soap and water using a non-abrasive cloth or sponge. Avoid harsh cleaners and opt for microfiber cloths to prevent scratches and maintain the pristine appearance. Address any scratches or damages promptly and consider applying a protective coating for added durability. Unlock the potential of colored stainless steel sheets and enjoy their long-lasting beauty. Explore our guide and elevate your projects today!

Understanding Colored Stainless Steel Sheets

A. What are Colored Stainless Steel Sheets?

Definition and composition of decorative stainless steel sheets, which are primarily made of iron, chromium, and other alloys for enhanced strength and corrosion resistance. – Explanation of the coloring process for stainless steel sheets, involving techniques such as powder coating, physical vapor deposition (PVD), or electrochemical coloring.

B. Types of Coloring Techniques

1. Powder Coating

Description of the powder coating process, where a dry powder pigment is electrostatically applied to the stainless steel surface and then cured through heat. – Advantages of powder coating, including a wide range of color options, excellent durability, and resistance to chipping or fading.

2. Physical Vapor Deposition (PVD)

- Overview of the PVD technique, where a thin layer of metal oxide is deposited onto the stainless steel through a vacuum chamber.

- Benefits of PVD coloring, such as high scratch resistance, enhanced color stability, and the ability to achieve unique finishes like brushed or mirrored surfaces.

3. Electrochemical Coloring

- Explanation of the electrochemical coloring process, involving the use of an electrolyte bath and an electric current to create oxide layers on the stainless steel surface.

- Advantages of electrochemical coloring, including precise control over color intensity, uniformity, and the ability to produce vibrant and consistent hues.

Applications of Colored Stainless Steel Sheets

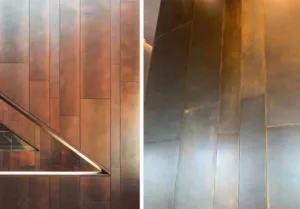

Exterior Facades

- Benefits of using colored stainless steel facades, such as enhanced aesthetics, durability, and resistance to harsh weather conditions.

- Examples of stunning architectural designs that incorporate colored stainless steel sheets, showcasing their versatility and impact.

Interior Walls and Partitions

- Advantages of using colored stainless steel sheets for interior walls, including easy maintenance, visual appeal, and the ability to create unique focal points.

- Creative applications in commercial and residential spaces, such as feature walls, room dividers, and decorative accents.

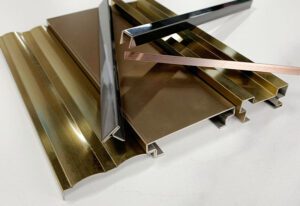

Decorative Features and Furniture

- Design possibilities with colored stainless steel sheets, such as custom furniture pieces, wall art, and decorative fixtures.

- Examples of decorative features and furniture using colored stainless steel, demonstrating the ability to add a modern and elegant touch to interior spaces.

Benefits of Colored Stainless Steel Sheets

A. Durability and Corrosion Resistance

Detailed explanation of stainless steel’s inherent properties that contribute to its durability, including resistance to rust, staining, and environmental factors. – Tips on selecting high-quality colored stainless steel sheets with superior corrosion resistance and longevity.

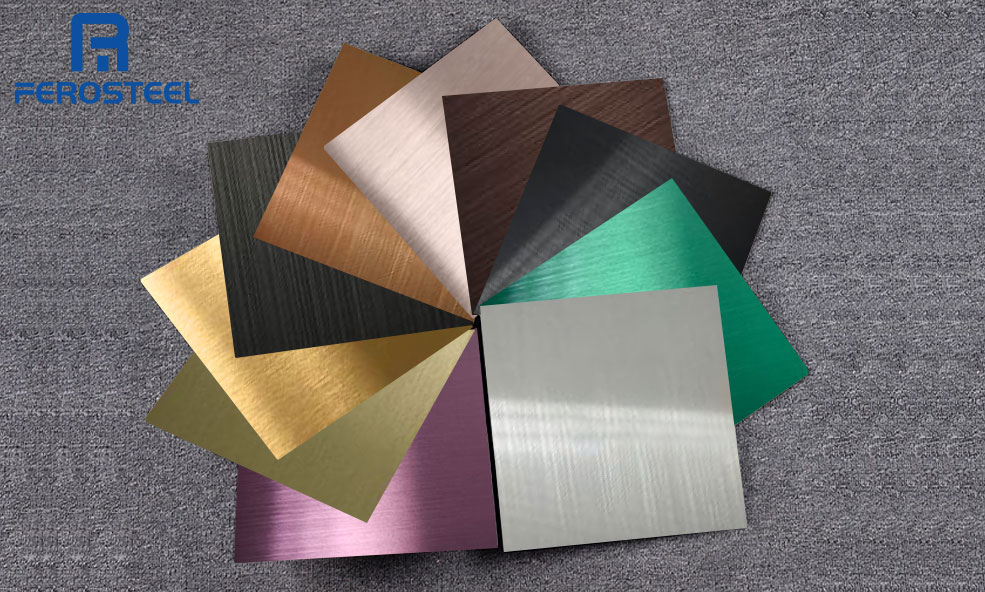

B. Aesthetic Appeal and Design Versatility

Highlight the wide range of vibrant colors and finishes available for colored stainless steel sheets, allowing for customization and seamless integration into various design styles. – Advice on selecting colors that complement the desired aesthetic and considering factors such as lighting, surrounding materials, and overall design theme.

C. Easy Maintenance and Cleaning

Colored stainless steel sheets not only offer aesthetic appeal but also boast low maintenance requirements, making them a practical choice for various applications. Here, we will discuss the simple steps for cleaning and preserving the appearance of colored stainless steel, ensuring its longevity and continued visual appeal.

- Routine Cleaning:

- Use a mild soap or detergent mixed with warm water to create a gentle cleaning solution.

- Apply the solution to a soft, non-abrasive cloth or sponge.

- Gently wipe the colored stainless steel surface, following the grain or brush marks to minimize the risk of scratches.

- Rinse with clean water and dry thoroughly with a clean, lint-free cloth to prevent water spots or streaks.

- Avoid Abrasive Cleaners:

- Refrain from using harsh or abrasive cleaners, such as scouring powders, steel wool, or abrasive pads, as they can damage the colored surface or leave visible scratches.

- Acidic or alkaline cleaners should also be avoided, as they can potentially discolor or corrode the stainless steel.

- Microfiber Cloths:

- Opt for microfiber cloths when cleaning colored stainless steel sheets. These soft and non-abrasive cloths effectively remove dirt, fingerprints, and smudges without causing scratches or streaks.

- Microfiber cloths are highly absorbent, reducing the risk of water spots during the drying process.

- Addressing Scratches and Damages:

- Promptly address any scratches or damages to maintain the pristine appearance of colored stainless steel.

- For minor scratches, consider using a stainless steel cleaner or polish specifically designed for colored surfaces, following the manufacturer’s instructions.

- Deeper scratches or damages may require professional repair or refinishing services to restore the original look.

- Protective Measures:

- Apply a clear protective coating or film to the colored stainless steel surface for added protection against scratches, fingerprints, and stains.

- Avoid placing sharp or abrasive objects directly on the surface to prevent potential damage.

- Regular Inspections:

- Regularly inspect the colored stainless steel sheets for any signs of wear, corrosion, or discoloration.

- Promptly address any issues to prevent further damage or deterioration.

- Recap the applications and benefits of colored stainless steel sheets, emphasizing their versatility, durability, and aesthetic appeal in various industries.

- Encourage readers to explore the possibilities of incorporating colored stainless steel sheets in their projects or products, highlighting the potential for enhancing visual appeal and functionality.

Frequently Asked Question

What are the benefits of using colored stainless steel sheets in architecture?

Colored stainless steel sheets bring a range of benefits to architecture, including enhanced aesthetic appeal, durability, low maintenance requirements, weather resistance, sustainability, and design versatility. With vibrant color options, long-lasting durability, and minimal upkeep, they offer architects the opportunity to create visually stunning and sustainable architectural designs.

How to clean and maintain colored stainless steel sheets?

To clean and maintain colored stainless steel sheets, use a mild soap or detergent mixed with warm water and a soft cloth or sponge to gently wipe the surface. Avoid abrasive cleaners, and opt for microfiber cloths to prevent scratches. Address any scratches promptly using a stainless steel cleaner or polish designed for colored surfaces. Consider applying a protective coating and regularly inspect the sheets for wear or damage.

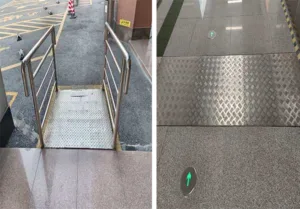

What are the popular applications of colored stainless steel sheets in the automotive industry?

Colored stainless steel sheets are widely used in the automotive industry for various applications. They are employed for exterior trim, interior accents, emblems and logos, exhaust systems, customization, and protective panels. These sheets enhance the aesthetic appeal, durability, and customization options of vehicles, making them a popular choice in the automotive sector.