Rigidized metals provide an innovative way to enhance the appearance and functionality of stainless steel surfaces. Through a specialized texturing process, these metals acquire unique patterns and textures, offering numerous benefits. In this comprehensive guide, we will explore the world of rigidized metals, with a focus on rigidized stainless steel, and delve into their applications, manufacturing process, and maintenance requirements.

Understanding Rigidized Metals:

A. Definition and Purpose: Rigidized metals refer to metals that undergo a specific texturing process to create patterns or textures on their surfaces. This process enhances their strength, durability, and visual appeal.

B. Rigidized Stainless Steel: Rigidized stainless steel is the application of texturing techniques to stainless steel surfaces. It offers distinctive advantages, such as improved grip, enhanced scratch resistance, and reduced glare.

The Rigidizing Process:

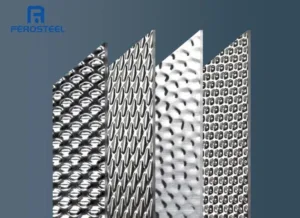

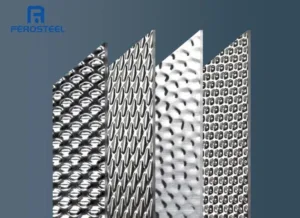

A. Methodology: The rigidizing process involves various techniques, including embossing, roller leveling, or diamond milling. These methods impart specific patterns and textures onto the metal surface, enhancing its aesthetic and functional properties.

B. Types of Rigidized Finishes: Different types of rigidized finishes exist, such as Diamond, Square, Quilted, or Traction Tread patterns. Each finish offers unique characteristics suitable for specific applications, allowing for customization and versatility.

Applications of Rigidized Metals:

A. Architectural and Interior Design: Rigidized metals find extensive use in architectural applications, such as wall panels, elevator interiors, and decorative elements. The textured surfaces create visual interest, adding a touch of sophistication and uniqueness to interior spaces.

B. Automotive and Transportation: In the automotive industry, rigidized metals are employed for car body panels, trims, and grilles. The textured finishes not only enhance the vehicle’s appearance but also reduce the visibility of fingerprints and provide improved grip for functional elements.

C. Industrial and Safety Applications: Rigidized metals have significant utility in industrial environments, including flooring, walkways, and machinery. The textured surfaces offer enhanced traction, reducing slipping hazards and improving safety in high-traffic areas.

Maintenance and Care: To maintain the longevity and aesthetics of rigidized metal surfaces, regular upkeep is essential. It is recommended to clean these surfaces with non-abrasive cleaners and soft cloths. Regular maintenance will preserve the texture and appearance of rigidized metals.

Advancements in Rigidized Metals:

In recent years, there have been exciting advancements in the field of rigidized metals, expanding their capabilities and applications even further.

Customization and Innovation: With advancements in technology and manufacturing techniques, rigidized metals can now be customized in more intricate and complex patterns. This level of customization allows for greater design flexibility and opens up new possibilities for architects, designers, and manufacturers to create truly unique and captivating surfaces.

Sustainable Solutions: Another notable advancement is the integration of sustainable practices in the rigidizing process. Many manufacturers are adopting eco-friendly approaches, such as using recycled metals and implementing environmentally conscious manufacturing processes. This not only reduces the environmental impact but also aligns with the growing demand for sustainable design and construction practices.

Digital Integration: Digital design tools and computer-aided manufacturing (CAM) technologies have revolutionized the rigidizing process. These tools enable precise and accurate pattern design, allowing for seamless integration of rigidized metals into complex architectural and industrial projects. Digital integration has also streamlined the production process, resulting in faster turnaround times and increased efficiency.

Collaborative Possibilities: Advancements in rigidized metals have encouraged collaboration between architects, designers, and manufacturers. By combining their expertise, innovative and groundbreaking projects have been realized, pushing the boundaries of what is possible with rigidized metals. Collaborative efforts result in unique solutions that blend functionality, aesthetics, and sustainability.

About rigidized metal

Can rigidized metal surfaces be customized with specific patterns or designs?

Absolutely! Rigidized metal surfaces can be customized with specific patterns or designs to suit individual preferences or project requirements. The flexibility of the rigidizing process allows for endless possibilities in creating unique textures and patterns.

Are rigidized metals more durable than standard stainless steel?

Yes, rigidized metals are generally more durable than standard stainless steel surfaces. The texturing process strengthens the metal, making it more resistant to scratches, dents, and wear. This durability makes rigidized metals suitable for high-traffic areas or applications that demand robust performance.

Can rigidized stainless steel be used in exterior applications?

Certainly! Rigidized stainless steel is well-suited for exterior applications. The textured surface not only adds visual interest but also provides improved grip and can withstand various weather conditions. However, proper maintenance and periodic cleaning are crucial to prevent the buildup of dirt and debris.

Conclusion: Rigidized metals, particularly rigidized stainless steel, offer a wide range of benefits, from enhanced aesthetics to improved durability. The texturing process creates visually appealing patterns and textures, making them suitable for architectural, automotive, and industrial applications. By understanding the manufacturing process, exploring different finishes, and maintaining rigidized metal surfaces properly, you can incorporate these remarkable materials into your projects and enjoy their unique advantages.